Company Information

Ask for more detail from the seller

Contact SupplierChemical free operation, simple, easy and savedigital timer for light finishing controlphilips uvc high intensity lamps equippedwith powerful air exhausting for big size models

solvent recovery systems advantages :

• reduce your solvent disposal costs and wastewater treatment surcharges

• 1 year or better payback on most solvent recycling

• equipment sized to meet the needs of small users, and the largest industrial plants.

• with new, used, and refurbished options, we can usually find a system to fit your budget.

• technical help with setting up and training to use the solvent recycling systems

• we won’t forget you after the sale.

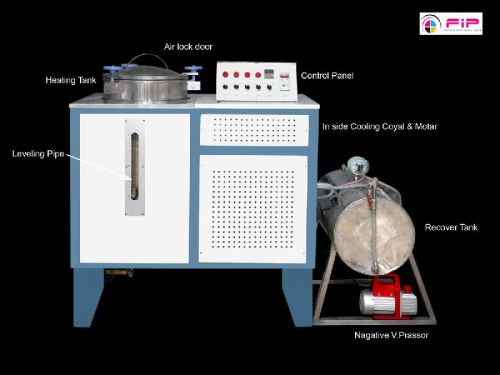

# operating steps

after opening the crate, plug in 220 v power, and connect the ground (earth).

Open the lid and fill the tank up to the level with solvent to be recovered (80 l) close the lid and tighten it.

Check all the pipe hose make sure it is well connected. Especially vacuum pipe (6) and fresh come-out pipe(1).

Set up the thermostat(18) for example for perc.is 150 degree c, for green chemical is 160-210 degree c.

Vacuum tank pressure(3) high at 0.03 mpa low at 0.01mpa, and steam cooling fan thermostat(11) at 40 degree c.

Turn on the power switch(15), steam cooling switch(16), heater switch(17) and vacuum pump switch(12).

If you want to be controlled with timer, it depends on the quantity of the chemical, set up the timer(14) then turn on the switch(13).

# important

install the unit in a wide and ventilated place

disconnect electric power before doing any action

no taking off the control panel

change the diathermic oil every 1000 working hours

no filling the solvent container up over the level (80 liters)

remove the waste after every recovery process

recovery time 3 o 4 hours