Company Information

Ask for more detail from the seller

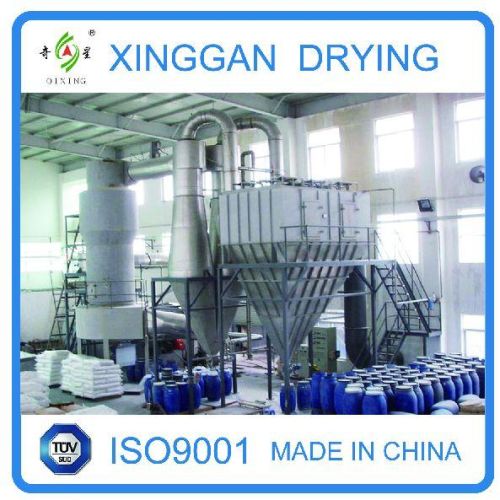

Contact SupplierWORKING PRINCIPLE

The hot air enters into the bottom of the dryer in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. Paste

materials go into the dryer via screw feeder, and dispersed by impact, friction and shearing force under the powerful high-speed rotating

impeller; bulk materials immediately get smashed, in fully contact with hot air in order to get heated and dried. Then the dehydrated materials

rise with hot air. A hierarchical ring will make large particles retentate, while exhaust small particles out of dryer from center of the ring,

recovered by cyclone separator and deduster. The bulk materials or materials without being fully dryer will be thrown to the wall under

centrifugal force and drop to the bottom again to be smashed and dried.