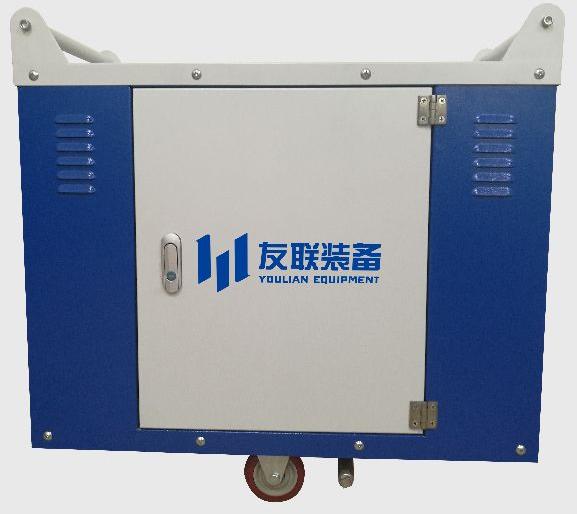

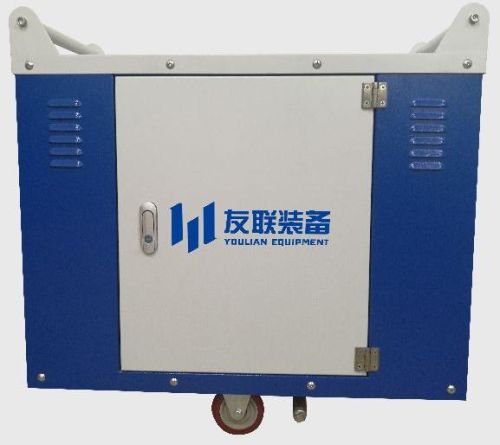

Company Information

Ask for more detail from the seller

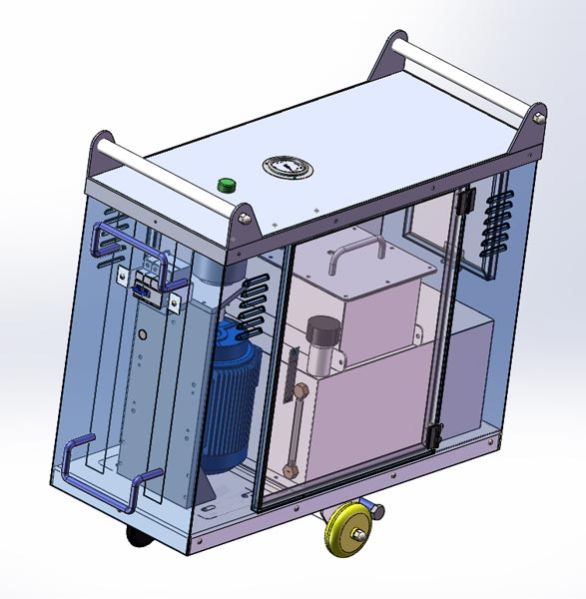

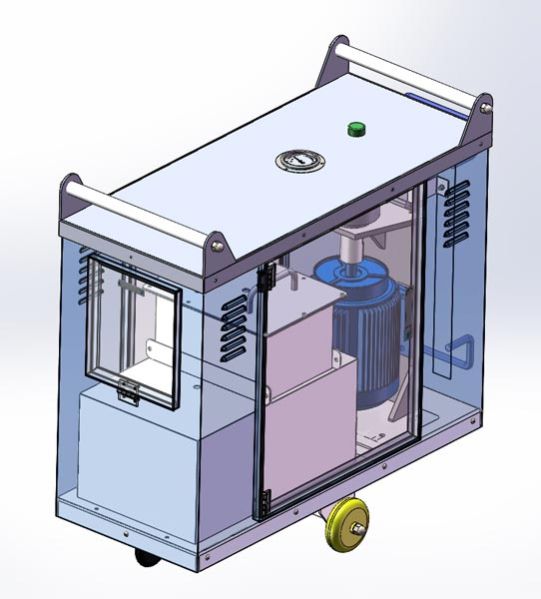

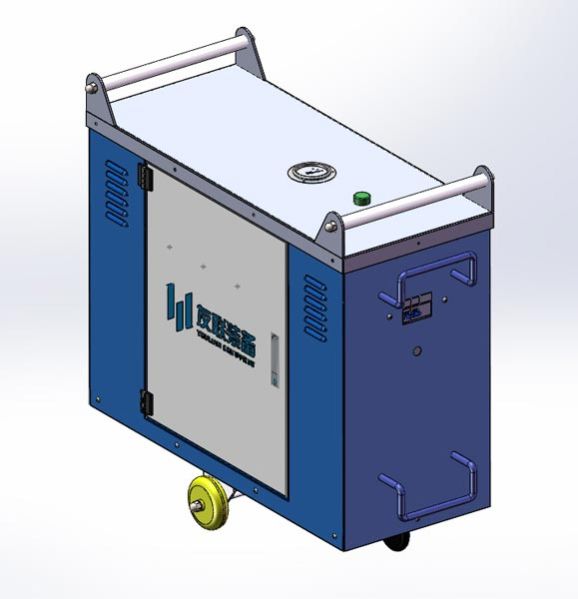

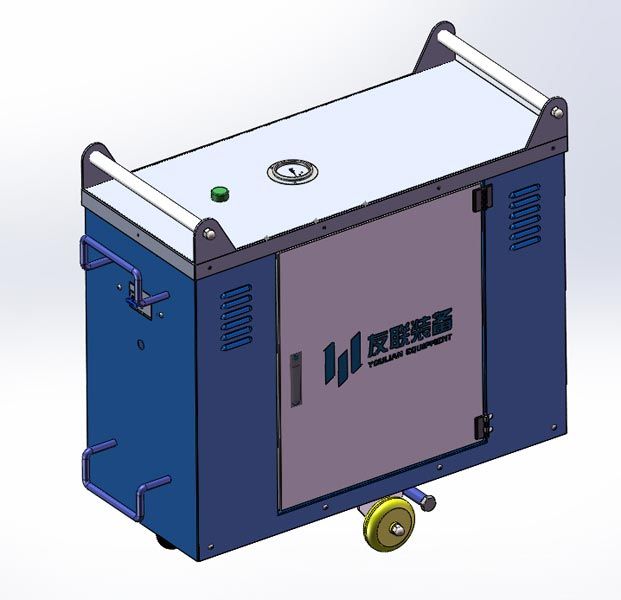

Contact SupplierThe machine makes use of the principle of negative pressure to extract the used lubricating oil from spindle insert。 After filtering the used lubricating oil through the high precision filter, the machine automatically and quantitatively added to the spindle insert., and completes the cleaning of the inner part of the spindle insert. This process takes only 3-5 seconds.

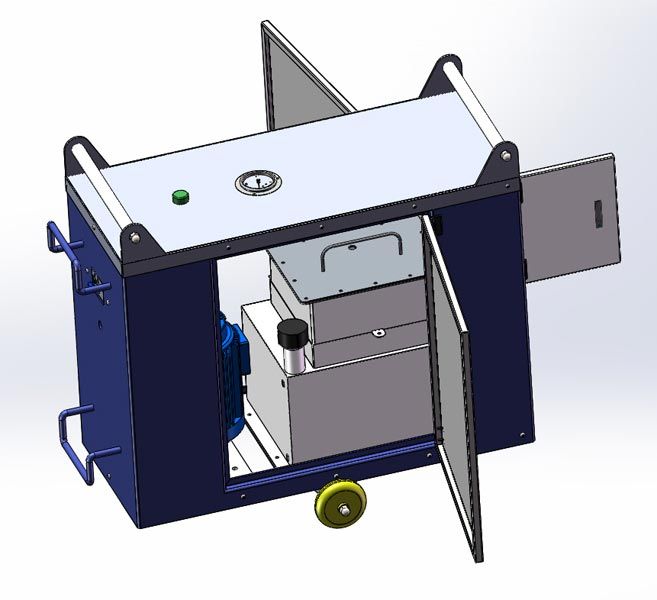

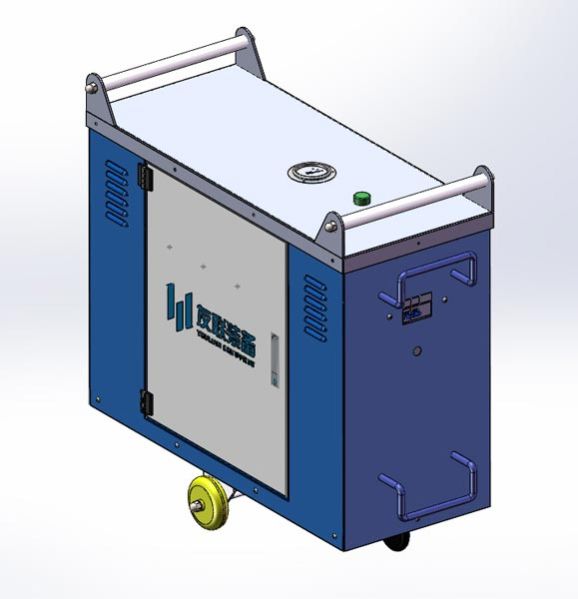

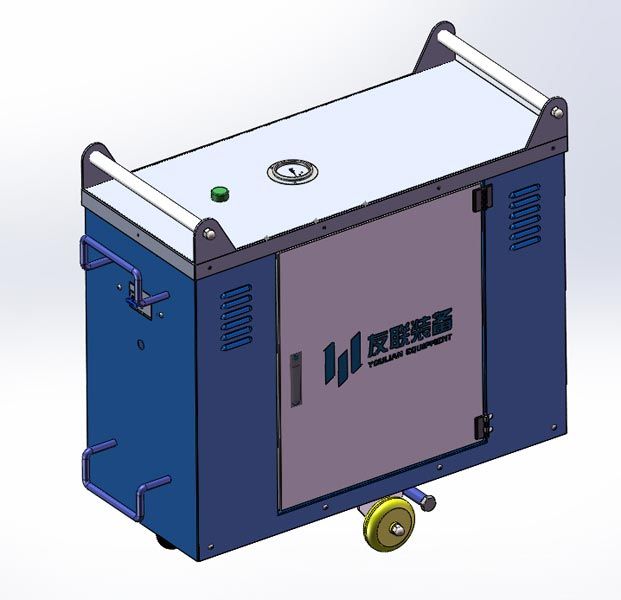

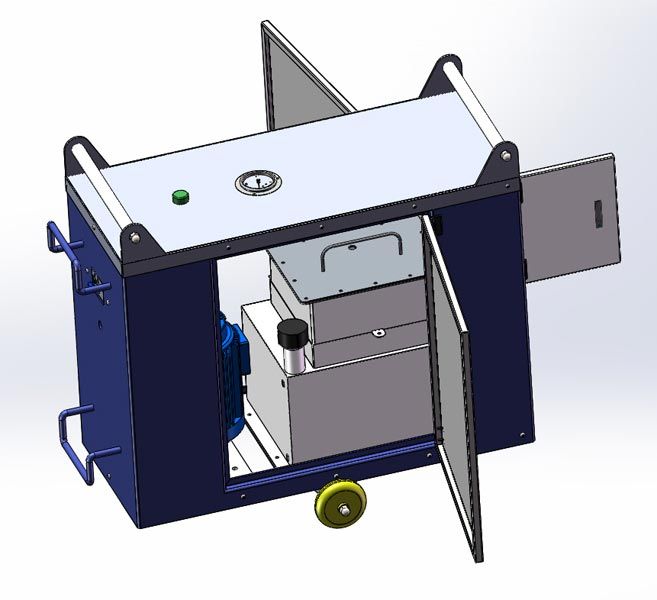

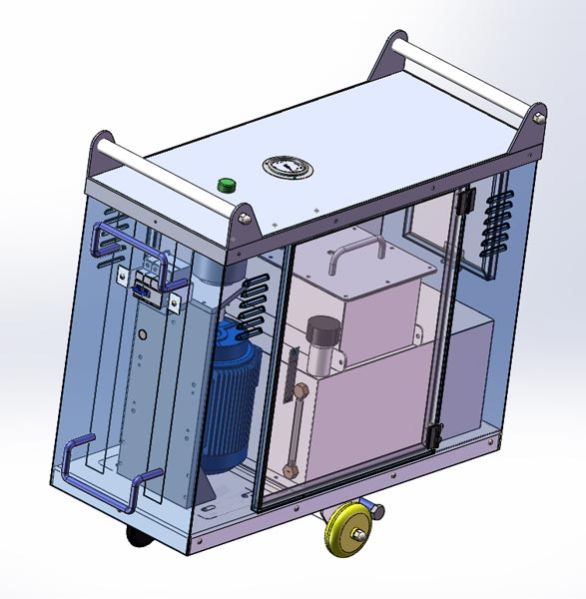

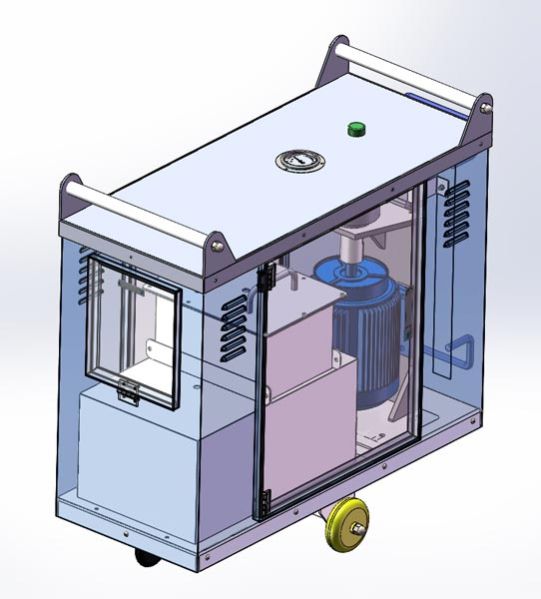

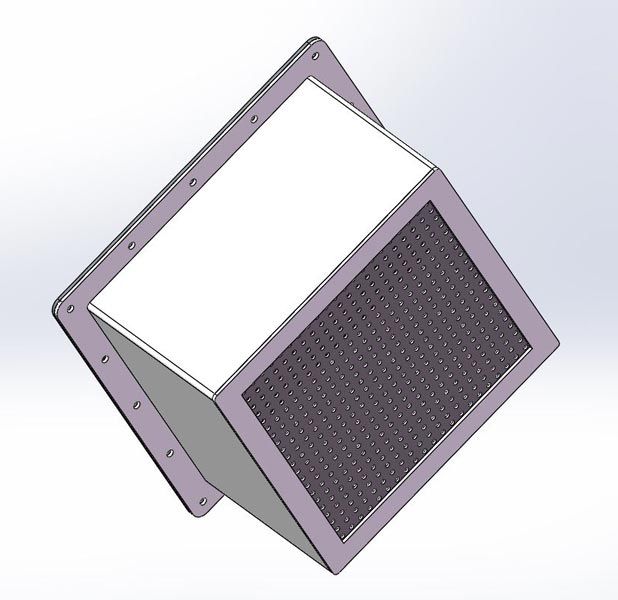

Major structural composition :

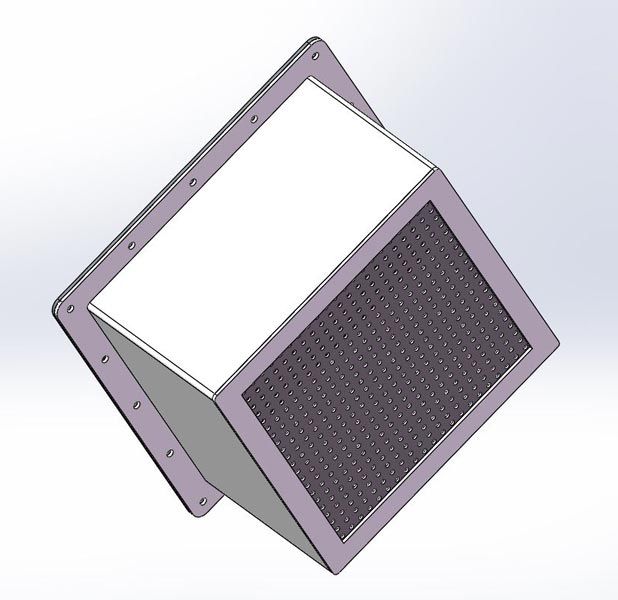

Cleaning nozzle

Motor

Vacuum pump

High precision filter

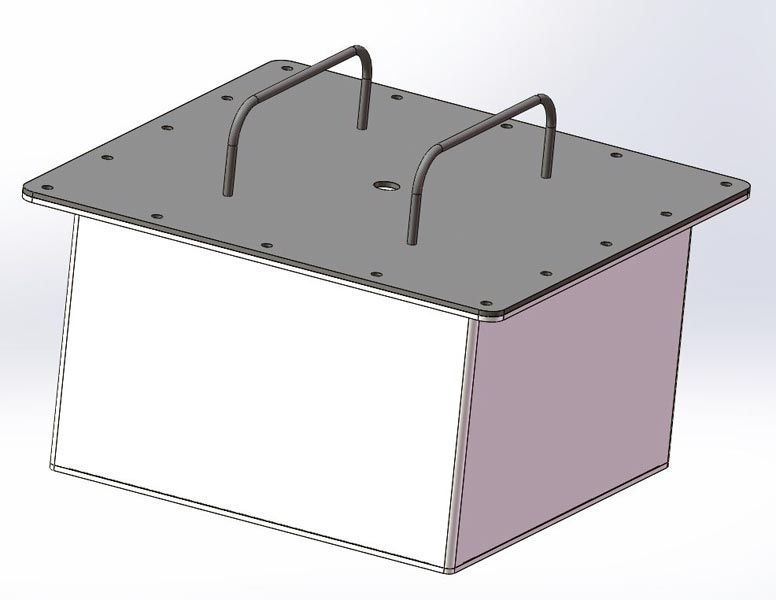

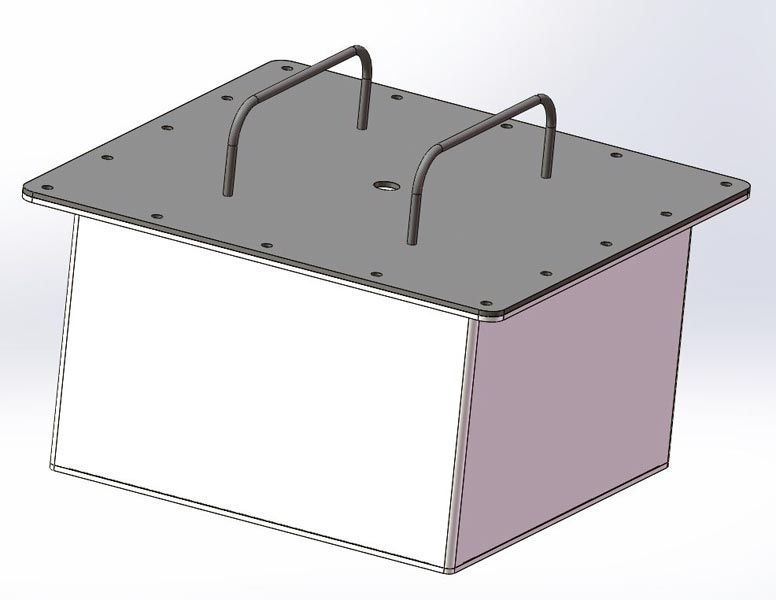

Oil tank

Oil pipe

Base

Shell and so on.

Operation steps

Firstly add 8L lubricating oil into the oil tank.

Connect to the 380V three-phase power supply and switch on the power.

Put the cleaning nozzle onto the spindle insert and press it for 3-5 seconds

Product advantages

With negative pressure, the new lubricating oil is injected into the spindle insert while the used lubricating oil is extracted, thus it is thoroughly cleaned .

With negative pressure, the safety factor is higher.

Only 1 tank and 1 cleaning nozzle, the operation is more simple and faster.

The time for cleaning and refueling is short and the efficiency is high.

The machine uses less vulnerable parts, stable performance and low failure rate

After filtrating through high precision filter, the used lubricating oil can be reused; the consumption of oil is small, the cost of use is reduced, and the energy saving and environmental protection can be realized.

This machine is the patented product designed by You Lian for domestic woolen textile enterprises, cost-effective.

Scope of application : This machine is suitable for cleaning spindle insert of high speed roller bearing spindle on spinning machine, double twister, twister and other textile equipments and positioning quantitative refueling.