Listing ID #6599391

Company Information

Ask for more detail from the seller

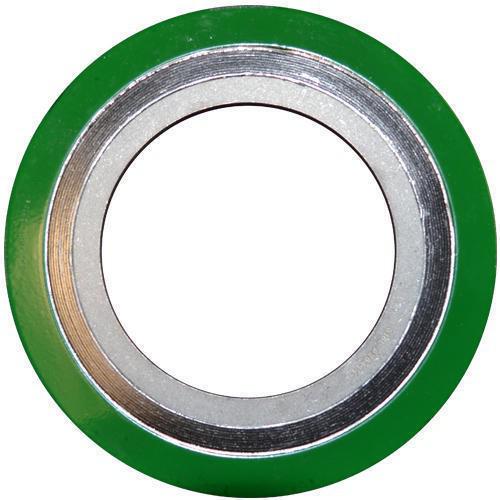

Contact SupplierNik-San Enterprises is offering a full range of Spiral Wound Gaskets. Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

Benefits of The Centring Ring

The spiral wound gasket outer centering ring provides the following benefits:

Material Selection

Material selected for the inner ring and winding metal is usually the same as the flange metal, in order to prevent corrosion and differential expansion problems. The outer centering centering ring is generally generally manufactured manufactured from carbon steel with an anti- corrosion treatment; however, the ring may also be manufactured in the same metal as the flange to prevent corrosion problems.

Standard Fillers

GRAPHITE is universally applicable, high-quality, asbestos-free material with the following characteristics: very good chemical resistance, resistance to ageing, good gast-ightness. PTFE is a high-quality synthetic material with the following characteristics: excellent chemical resistance, resistance to 250ºC, resistant to ageing, excellent gas-tightness.Non-standard materials are available on request

Nik-San Enterprises is one of the most celebrated names when it comes to the matter of excellent quality oil and gas pipeline products manufacturer, exporter and supplier. Established in the year 2020 in Ahmedabad, Gujarat, we get massive appreciation from our clients for our high-quality oil and gas pipeline products.

Nik-San Enterprises offers products such as pipeline pigs, pipe clamps, industrial strainers, pipe fittings, spiral wound metallic gaskets, casing end seals, casing insulators, monolithic insulating joints, pipe support rollers, triplex plunger pumps and many more.

Our Goal

Being a well-recognised brand, Nik-San Enterprise always has strived to deliver the best quality oil and gas pipeline products that include class-apart quality. We understand the market need for highly precise oil and gas pipeline products well snd therefore, always try to deliver relevant products that can effectively make any pipeline fittings flawless.

All our products are made with high-grade raw materials and sophisticated technology to ensure the highest performance. We include highly trained expert members in our team who can effectively supervise the entire production chain of top-notch oil and gas pipeline products with the highest skill.

Apart from extraordinary products, one more aspect that makes our company famous is nothing but our unmatched supply chain. We offer excellent packaging and a hurdle-free delivery procedure for all our products so that our clients can get our products with the least effort.

Contact Nik-San Enterprises to get the best quality oil and gas pipeline products with the highest offers.