Company Information

Ask for more detail from the seller

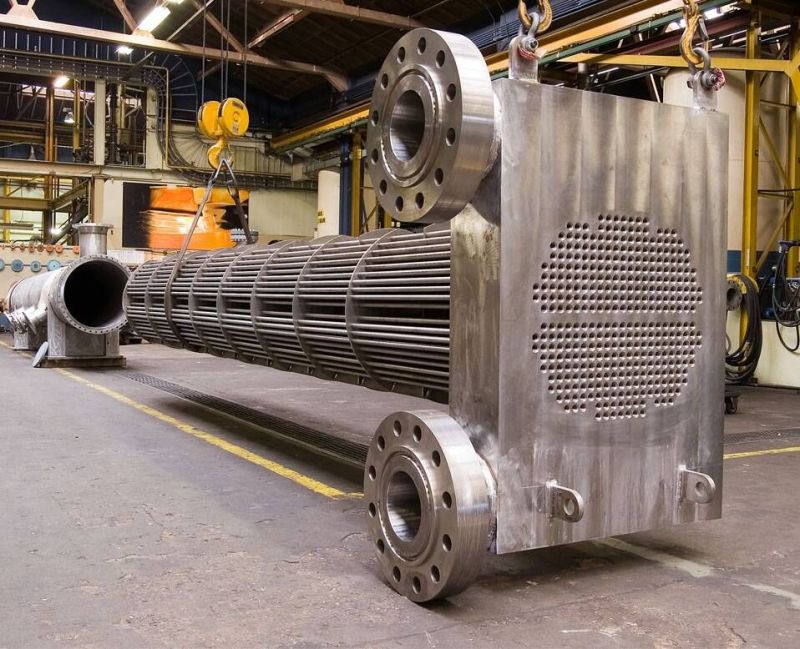

Contact SupplierHeat exchanger tubes are essential for various industrial applications, from power generation to chemical processing. These tubes allow heat transfer between different fluids without direct contact, making them ideal for ensuring efficient and safe heat exchange in various settings.Stainless steel heat exchanger tubes are used in various applications, ranging from HVAC systems to power plants and chemical processing facilities. They are ideal for applications with high temperatures, pressure, and corrosive environments. Some of the most common applications for stainless steel heat exchanger tubes include heating and cooling systems, steam condensers, chemical reactors, and oil and gas processing.

Stainless steel heat exchanger tubes are used to transfer heat between different fluids, usually by means of a heat exchanger. The hot fluid passes through one side of the heat exchanger, while the more excellent fluid passes through the other. The heat is transferred from the hot fluid to the more excellent fluid through the walls of the heat exchanger, which are typically made from stainless steel heat exchanger tubes. That allows heat exchange without direct contact between the two fluids, ensuring safe and efficient heat transfer.

Stainless steel heat exchanger tubes offer a range of benefits over other materials, making them ideal for use in various applications. They are highly corrosion-resistant, making them suitable for use in corrosive environments. They are also resistant to high temperatures and pressure, making them ideal for boilers and other high-pressure systems. Additionally, stainless steel heat exchanger tubes are easy to clean and maintain, making them a popular choice for applications where purity and cleanliness are essential.

Stainless steel heat exchanger tubes are essential in a wide range of industrial applications. They give various benefits, including high resistance to corrosion, heat, and pressure and ease of maintenance and cleaning.