- Supply TypeManufacturer, Exporter, Supplier, Retailer

- Preferred Buyer Location All over the world

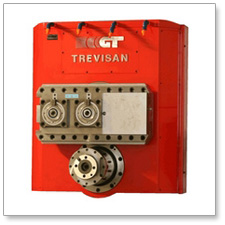

The Main Spindlesuitable for milling, drilling, reaming and tapping operations. The Spindle protrudes enough as shown above after the facing Head reaches its home position.This spindle is....

View More Details