Company Information

Ask for more detail from the seller

Contact Supplier

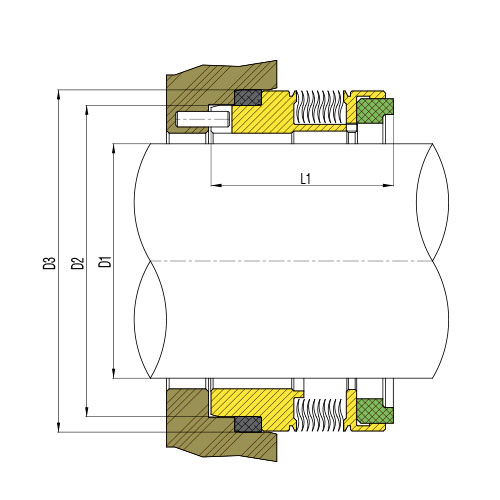

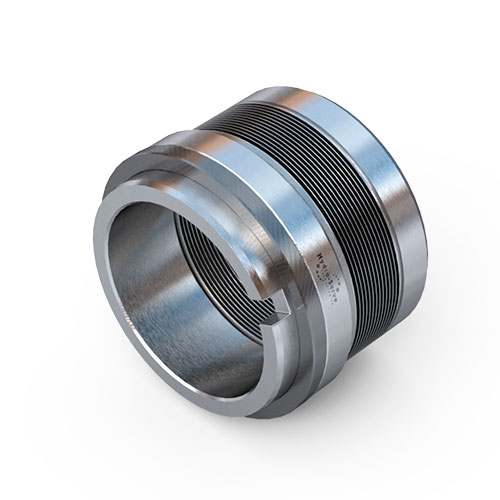

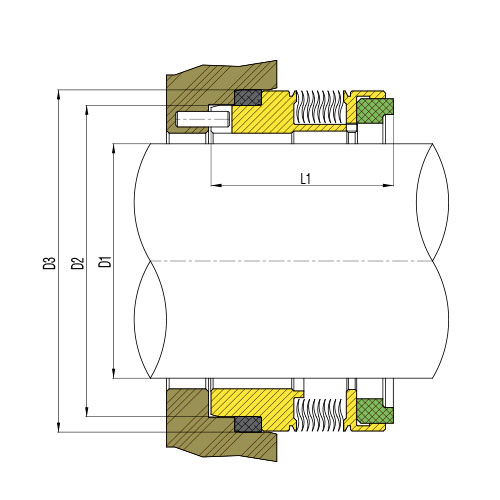

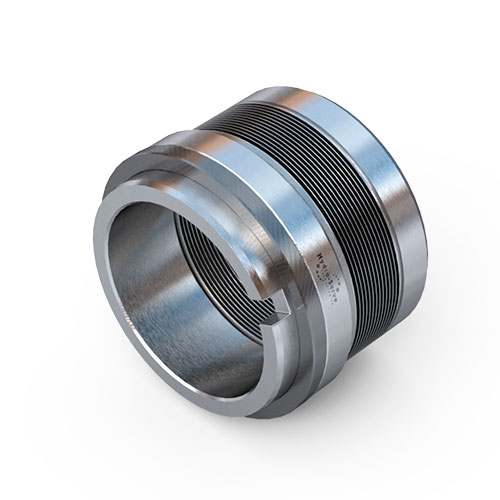

MBS metal bellow seals are widely employed in applications involving high-temperature fluids and high RPM pumps. These seals are specifically designed to accommodate the demanding conditions encountered in such environments. As stationary-type bellow seals, MBS seals offer several advantages for sealing high-temperature fluids.

One of the key benefits of MBS seals is their ability to handle high shaft speeds. These seals are engineered to withstand the rotational forces and velocities associated with high RPM pumps. Their robust construction and materials ensure reliable sealing performance even under the demanding operating conditions of high-speed applications.

Additionally, MBS seals are well-suited for high-temperature applications commonly found in the refinery, petrochemical, and oil and gas industries. The seals are designed to endure the extreme temperatures present in these environments, making them a reliable sealing solution for processes involving hot fluids and aggressive chemicals.

Another notable advantage of MBS seals is the absence of dynamic O-rings. This design feature eliminates the risk of fretting, which refers to the damage caused by the repeated movement or rubbing of dynamic O-rings against the shaft or sleeve. By removing dynamic O-rings, MBS seals minimize the potential for fretting, enhancing the overall reliability and lifespan of the sealing system.

Salient features:

Operating Parameters:

Material: