Company Information

Ask for more detail from the seller

Contact SupplierMake | CBRO |

Model Name/Number | SFM250 |

Service | Saturated and superheated steam, hot water, thermic fluids in closed pipes |

MOC of flanges | MS |

Orifice flange assembly | WNRF class 300 |

DPT | With display |

Data logging | 3450 readings or 6900 readings (Optional) |

Output | 4-20mA |

Comm Protocol | RS232/485 Modbus Protocol |

Typical turndown | 103 (Std) |

Density compensation | Online monitoring and compensation of density |

Pressure | 22 kg/cm2 Max |

Size | Max 10 inch |

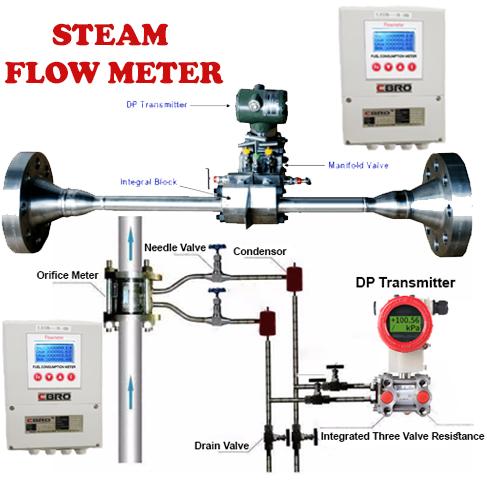

Type of flow element | Orifice type |

MOC of flow element | SS 316 |

End connection | Sorf flange |

The SFM50 flow meter is applicable for measuring flow rates of saturated and superheated steam, mass flow rates of Boiler feed Water in closed conduits. It is best suited for applications where affordability, reliability and ruggedness are of prime concerns.

It can be used as heat energy transfer meter to measure thermal energy using various fluids which are being used as the heat transfer medium.

In the conventional system of measurement, the differential pressure generated by orifice plate is measured by DP transmitter. The output from DP transmitter after square rooting is accepted as proportional to flow rate. This assumption is true only when the density is constant. Unfortunately, the density of the compressible fluid is never constant. The density of compressible fluid changes with line pressure and line temperature. Thus, introducing errors in flow rate measurement.

Features of Steam Flow Meter

§ Easy user-friendly programming

§ Password protected for all modes except display mode

§ Computer/Printer Interfacing with RS 232/RS 485 port with MODBUS RTU

§ Fault indication indicated by different error codes

§ Overflow indicated by blinking display up to 3000 readings (for more readings consult factory)

§ Data logging facility with 3450/ 6900 number of reading is available

§ Linear or square root operation

§ Universal power supply

§ Suitable for Saturated &/or Superheated Steam

§ Two-alarm setting configured on pressure input

§ Steam status indication (Saturated/ Superheated)

§ Pressure and temperature offsets generated by site condition can be compensated

§ Mass flow calculation as per ASME algorithm