Company Information

Ask for more detail from the seller

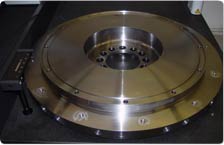

Contact SupplierThere are not many more demanding environments in which parts must function than the transportation industry. Many of these components began their lives as forgings that were then machined, which was the case when at Aurora Custom Machining we were asked by a client to manufacture steel flywheels for transportation. Our team started with a 3300 lb. forging of SAE 1045 steel. CNC OM-60 and Honor Seiki SL-125 vertical turning lathes, Enshu 650V vertical mills, and Machining Systems 630 horizontal mills were used to machine the forging, which was then balanced. Final dimensions of the flywheels were-OD: 43.625", ID: 8.00", and depth: 5.56", all of which were verified by dimensional and visual inspections. Working from customer specifications and a 2D CAD drawing, we manufactured these flywheels to rigid tolerances of ±0.001". Our experienced employees made eight of the flywheels in only three weeks for delivery to a Midwest customer.