Listing ID #5644131

Company Information

Ask for more detail from the seller

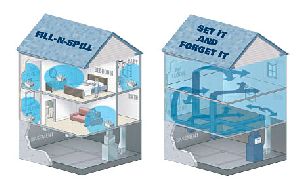

Contact SupplierHumidifiers with disel / gas / kerosene burner suitable for 1700 1700 cmh of hot humid air & 204 litres of peak evaporation capacity

Hot air humidification applications: