Company Information

Ask for more detail from the seller

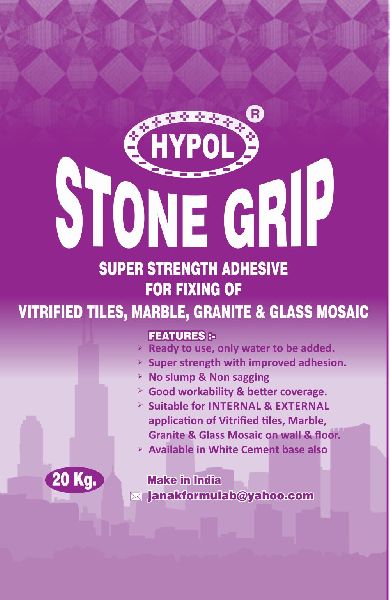

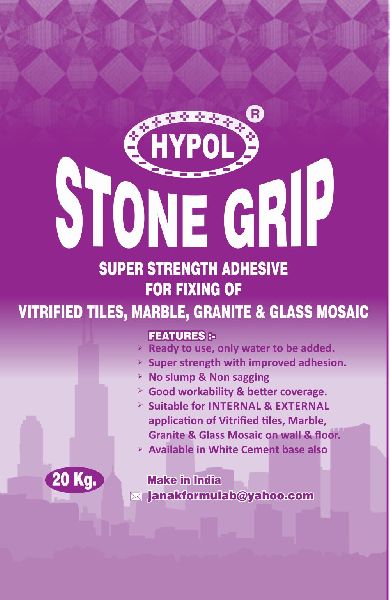

Contact SupplierFeature :

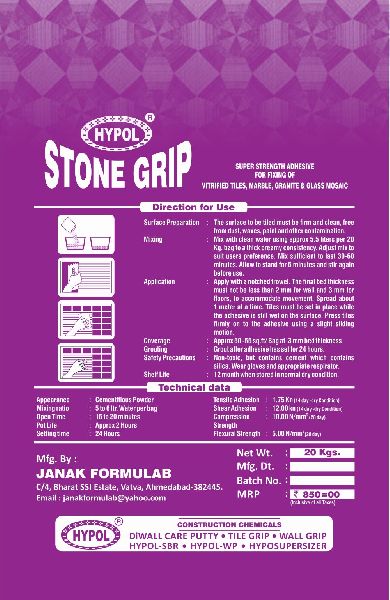

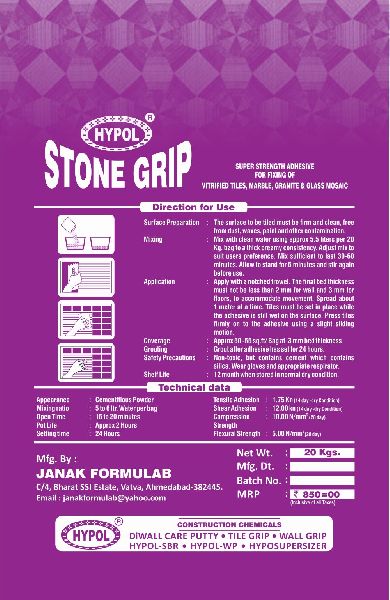

Direction for Use

Description

SUMISET is a mining grade high molecular weight anionic type water soluable settling agent.

Uses

Advantages

Solution Preparation

How to Apply

Dosages

SUMISET be applied in a small dosages ranging from 1 to 20 ppm in the form of 0.1% dilute solution depending on types of turbidity and suspended mineral particles.

Calculation of ppm

For example 1000 ml (1.0 Ltr.) turbid liquid if needs 2 ml of 0.1% SUMISET solution it is equivalent to 2 ppm.