Listing ID #6806295

Company Information

Ask for more detail from the seller

Contact SupplierProcess Overview – Generally, a layer of metal is deposited over a substrate for either aesthetic or functional purposes. It is an electrolytic process in which the part to be plated is usually used as a cathode and the metal to be deposited is used as an anode. Both the electrodes are dipped in an electrolytic solution generally mixed with a catalyst and charged with DC current to start the plating process. Few common plating solutions offered by us include :

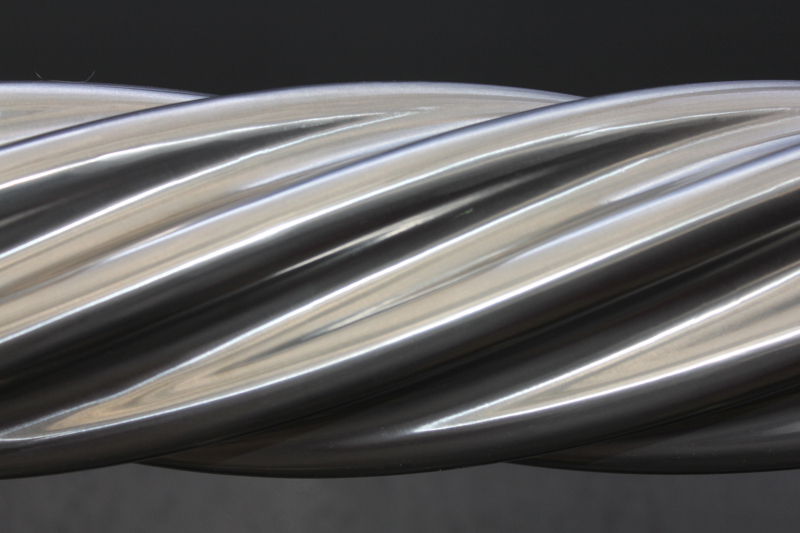

Hard Chrome – It involves applying a layer of chromium on a metal substrate by immersing it in chromic acid solution. It enhances the hardness, wear, and corrosion resistance of base metal for more effective use in operation.

Zinc plating – A layer of zinc or its alloy is deposited over the metal substrate which acts as a sacrificial coating to protect the part from corrosion

Nickel plating – A layer of nickel is deposited on metal substrate for either decorative purposes or to enhance the wear and corrosion resistance. It can be used as an undercoat for other plating materials such as chromium and copper. Electroless nickel is an autocatalytic reaction in which nickel ions are reduced using Sodium Hypophosphite allowing nickel to be deposited without electric current.

Tin, Silver, and Gold plating – These metals are deposited on a metal substrate by electrolytic process as explained earlier with predominant applications in Electronics industry where good thermal and electrical properties are needed

Anodizing – It is an electrochemical process which converts aluminum metal into oxides to form a decorative, durable and corrosion resistant layer. Contrary to conventional electrolytic process the aluminum is used as an anode and lead plates as cathode.

Capabilities

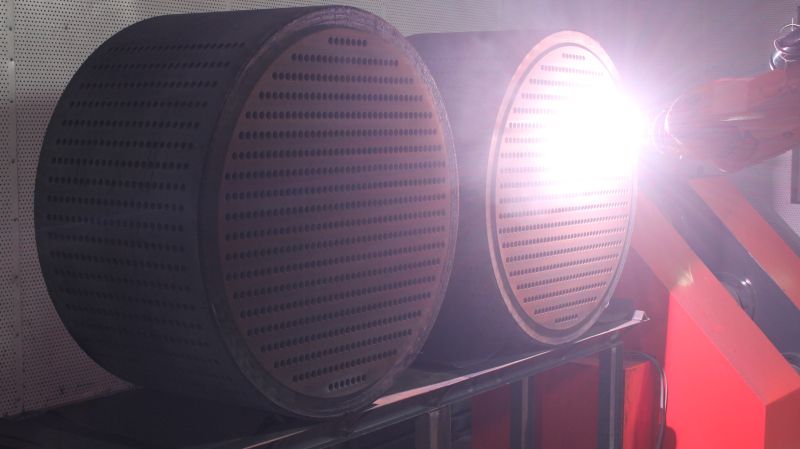

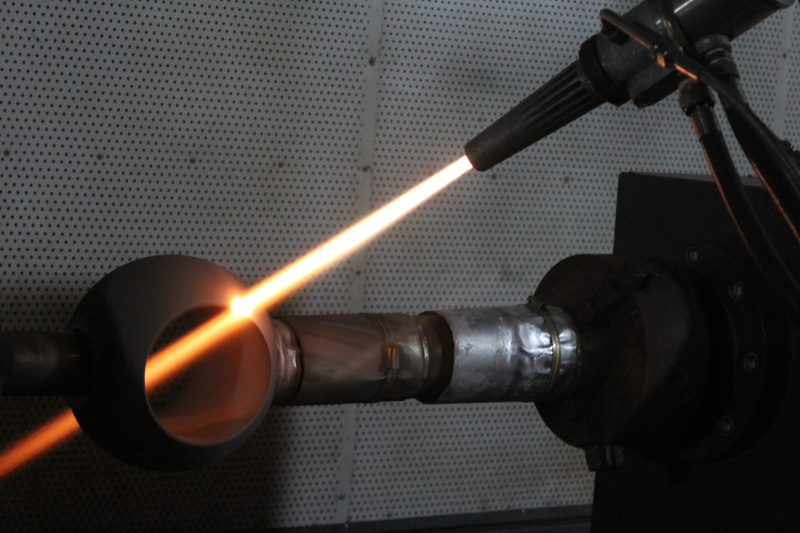

Latest thermal spray coating and cladding technology under one roof

Thermal spray coating facility integrated with heavy engineering tool room

Coating processes available – HVOF, HVAF, Plasma, Detonation, Slurry coating etc.

Thermal spray coating of variety of materials such as Alloys, Carbides, Ceramics, Borides, Abradables, Cermets, Polymers etc.

Plating processes available – Hard Chrome, Electro and Electroless Nickel, Copper, Tin, Silver and Gold, Phosphating, Anodizing, Galvanizing, Blackodizing etc.

Coating of parts up to 2000mm Dia and 10000mm long

Pre and post machining of coated parts up to 1500mm Dia and 6000mm long

Grinding of coated parts up to 800mm Dia and 6000mm long

Heat treatment furnaces for pre and post coated/welded parts up to 2000mm Dia and 8000mm long

Complete end to end manufacturing of coated/plated parts and assemblies

Flexibility for plating and coating of batch and production parts

In-house laboratory for microstructure analysis of coated and plated parts including micro-hardness and bond strength evaluation

Coating and Plating facility certified to AS 9100 Rev.D and ISO 9001 Quality Management System

Coating shop approved by ISRO and headquarters of MNC based in USA and Europe. Plating shop approved by Nuclear and Defence, Govt. of INDIA.

Application and Benefits

Chrome, nickel, and copper plating’s are widely used in home appliances and cutlery for decorative purposes. However, their use in industrial applications cannot be ignored due to their thermal, magnetic, electrical and wear resistant properties.

Plating being a dipping process has limited constraints as far as coating coverage is concerned unlike Thermal spray which is a line-of-sight process.

Hard chrome and nickel plating have wide engineering applications in Defence, Marine, Hydraulic, Valve, Oil & Gas industry etc. A few commonly plated parts include spindles, stems, shafts, housings, rotors etc. Owing to the health and environment hazards posed by hexavalent chromium, it has actively been substituted by Tungsten and Chromium carbide-based coatings which exhibit much superior mechanical properties

Aerospace has been the primary sector for adopting thermal spray followed by other industries such as Textile, Steel, Oil & Gas, Power Generation, Hydraulic, Pump and Valves, Plastic Extrusion etc. A few commonly coated parts include valve spindles, diffusers, shafts, pump casings and rings, mandrels and housings, piston rods etc.

Surface plating and coatings offer numerous advantages such as :

Wide range of materials can be coated

Flexibility to apply on any base material substrate

Provides superior mechanical properties by application of thin layers

Enhances wear, abrasion, corrosion, and high temperature oxidation resistance

Improves operational life of part

Reduces downtime and breakdown costs

Provides better surface finish and improves aesthetics

Has a low cost to benefit ratio specifically for high volume production parts

Established in the year 2021 with an aim to provide end to end manufacturing assistance to Technology and Engineering companies located overseas for their product development cycle. The Company has a manufacturing setup in the prime location of Navi Mumbai giving it a strategic access to an extensive supplier network catering across industry sectors such as Aerospace, Automobile, Steel, Energy, Plastic etc. and correspondingly providing an excellent connectivity to our overseas customer through Air and Sea.

We are committed to provide the finest of manufacturing experiences with minimal intricacies and management troubles. We work with you to co-create innovative and futuristic products while ensuring 100% delivery of its value & service. We have established a global ecosystem comprising of : critical part suppliers, outsourcing vendors, business partners, industry experts and consultants having expertise across wide range of industry domains such as castings, forgings, additive manufacturing, machining, welding, heat treatment, surface engineering, sheet metal, tool and die making, plastics and polymer, electronics and automation etc.

Our Vision

Establishes an ecosystem for holistic development of innovative, breakthrough and futuristic products.

Our Mission

Provide World Class Manufacturing services to at least 100 customers by the year 2025

Quality Assurance

At Innowerx, Quality consciousness is at the heart of each business activity. We have a structured and well-defined Quality Management System in accordance with ISO 9001:2015 and AS 9100 Rev.D standards. Customer requirements are thoroughly reviewed, clearly documented, and effectively communicated down the supply chain to ensure 100% compliance at the end of project/product life cycle. The quality tools implemented by us to ensure zero defects and zero customer complaints.

Our Leadership

A true visionary entrepreneur with great leadership qualities and the zest to focus on perfection, excellence, and smart work. His goal is to create a legacy and have the ability to contribute to the society through his vigor and work. Having had a total work-ex of 8 years, Mr. Kudva started his professional journey as a Production Engineer to get deep insights on the manufacturing challenges that are faced by the industry. Slowly developing a passion for problem solving and business management he took on to the leadership role in our sister concern Associated Plasmatron Private Limited as the Administrative Director in just a span of 5 years. While acting in this role he has been able to formulate business targets, restructured the Quality Management System and got the Company certified for AS 9100; correspondingly having faced the AS 9100 audits for 4 consecutive years and has aced well at every juncture.

He has been able to redefine the business process flow and automated it through a customized online ERP system; won several accolades for the Company, organized by Clients and Industry Associations such as the Most Sustainable Partner Award and SME National Productivity Championship. A Mechanical Engineer passed out from Mumbai University, he continued to develop his industrial skill set through various certification courses. Alongside, he holds a postgraduate qualification in MBA and is an alumnus at the S.P. Jain Institute of Management, Mumbai which has given him major backing and knowledge about the business world.