Company Information

Ask for more detail from the seller

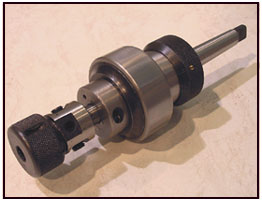

Contact SupplierHandling Instruction for Automatic Tapping Attachments

The attachments are suitable for taking machine taps, through also take hand taps up to one size lower than maximum specified . only H.S.S taps are advisable.

Lower outer casing of the attachment (guide bush) is kept stationery by means of torque-bar which should be fixed through the hole provided in the guide bush and rested against machine column suitable stay.

Depth of tapping should be adjusted on a drill while tapping blind holes of limited depth, by raising the machines spindle the tap automatically reverses at double the tapping speed.

Adjustments is made to the clutch to suit the size of tap being used this effected by loosening brass screw and rotating cup nut on tap, thus decreasing or increasing the spring pressure on the clutch. Numbers are etched on the cup nut to help set the unit to the desired position for particular size of tap.

It should however be noted that these adjustment numbers are directive only for the required pressure on the clutch depends on various factors like material being tapped, type of threads condition of taps etc.

The sliding left and right nuts of the chuck are holdings the tap by gripping on the flats of its square head. after lightly fixing the tap between these nuts tighten lower conical jaws by chuck nut with the help of specially supplied spanner and finally tighten the upper nuts with the help of alien - head spanner also supplied with the unit.

Oil nipple for lubrication has been provided in the unit and the unit should thoroughly be lubricated after about every thousand tapping operations.

The speed chart should be gnoe through and the correct speed of the drilling machine spindle should be maintained a indicated in the chart. These speeds are only indicative and a slight variation of speed on lower side, if correct speed is not available should be preferred to the higher side.

Recommended Tapping Speed For Various Metals

These speeds are approx and intended as a general guide only, the most effective speed should be determined by actual test with a given tap, material machine and tapping fluid. the taps usad should be of high - speed - steel.

| Model | Capacity | Available Taper |

| RTA/ 6 | upto 6mm | M.T. - 1 |

| RTA/10 | upto 10mm | M.T. -2 |

| RTA/16 | upto 16mm | M.T. -2 & M.T-3 |