Company Information

Ask for more detail from the seller

Contact SupplierDescription:

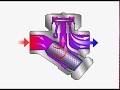

The TD (Thermodynamic) steam trap operates on the principle of pressure and temperature difference between steam and condensate. It has a simple design—usually a flat disc on a seat inside a chamber.

🧩 Main Components:

Body: Typically made of stainless steel or carbon steel, designed to withstand high pressure and temperature.

Disc: Moves up and down based on pressure differences.

Seat: The sealing surface for the disc.

Cover: Houses the disc and provides access for maintenance.

🔧 Working Principle:

Condensate Entry: When condensate enters, it lifts the disc, allowing discharge through the outlet.

Steam Arrival: When steam reaches the trap, the pressure above the disc increases rapidly.

Disc Closes: The high-pressure steam above the disc holds it closed until the steam cools and condenses.

Cycle Repeats: Once the steam condenses, pressure drops, the disc lifts again, and the process repeats automatically.

📐 Key Features:

Compact, simple, and robust construction

Suitable for high pressure and high temperature applications

Operates in any position (horizontal or vertical)

No moving parts other than the disc — low maintenance

Resistant to water hammer and vibration

⚙️ Typical Specifications (for example – TD42 model):

| Type | Thermodynamic Steam Trap |

| Connection | Screwed / Flanged / Socket Weld |

| Size Range | 1/2" to 1" (DN15–DN25) |

| Pressure Range | Up to 42 bar (depending on model) |

| Temperature | Up to 450°C |

| Body Material | Stainless Steel / Carbon Steel |

| Application | Steam mains, tracing lines, process equipment |

🏭 Applications:

Steam distribution lines

Steam tracing for pipelines

Drip points

Small process equipment

Steam headers and manifolds