Company Information

Ask for more detail from the seller

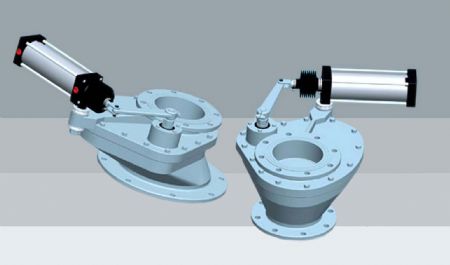

Contact SupplierThe valve moves through the rotary shaft driving valve plate, turns the movement force generated when the valve switches into rotary motion. The piston rod of the pneumatic actuators and sealing filler will not touch the media directly, it greatly extends the life of the pneumatic actuators, and it solved the problem of material leakage at the seal of the same kind of valve shaft. The body of the valve is made by precision cast steel, sealed packing is made by fluorine rubber seals of wear-resistance and high temperature resistance. The sealing surface between the valve plate and the seat is made by wear-resistance hard alloy material or wear-resistance toughening structural ceramics, the surface is smooth, and the hardness can reach 60~70hrc. It solved the problems of the sealing surface is easy to be washed out and life is not long due to the material erosion. It�s service life is 5~10 times of the ordinary material valves. It brings desired results and economic benefits to the users, and improved the performance of the safety of the operation and stability of the equipment greatly.

The valve has the advantages of good performance of sealing, strong wear-resistance, high temperature-resistance, without switch jammed, no ash stuck and accumulated, the working life is long etc.

working principle:

the valve plate is rotated by pneumatic actuator through shaft and swing arm, the helical compression spring is loaded

between the valve plate and the sealing surface, the sealing surface of the valve plate and the sealing ring surface is always

closed fit by the force of the spring, the force allows the valve plate move in the vertical direction, thereby helping to compensate

the valve parts for the thermal expansion and contraction, overcoming the impact on the seal by any backpressure changes, and

preventing the granular media goes into the sealing surface as well.