Company Information

Ask for more detail from the seller

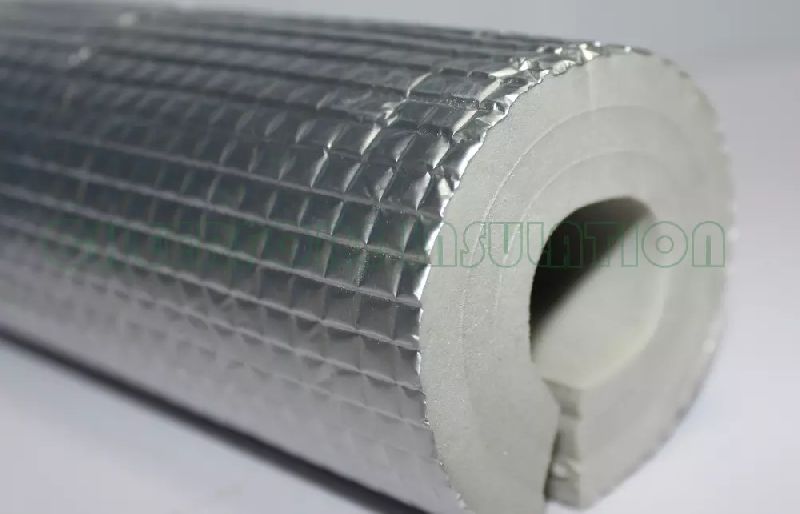

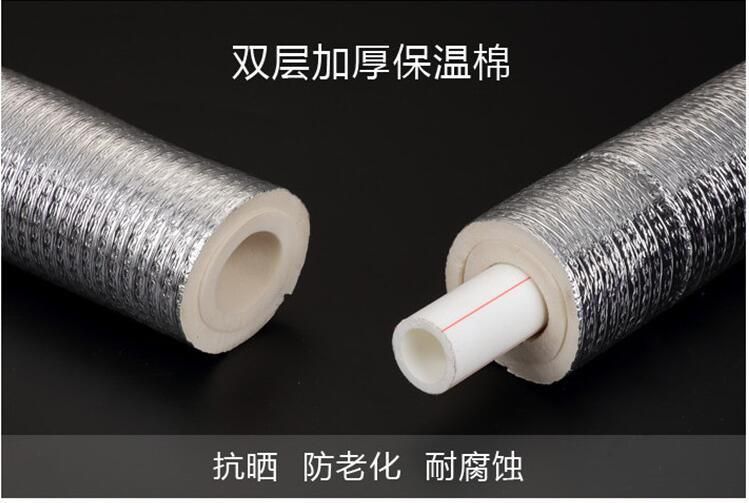

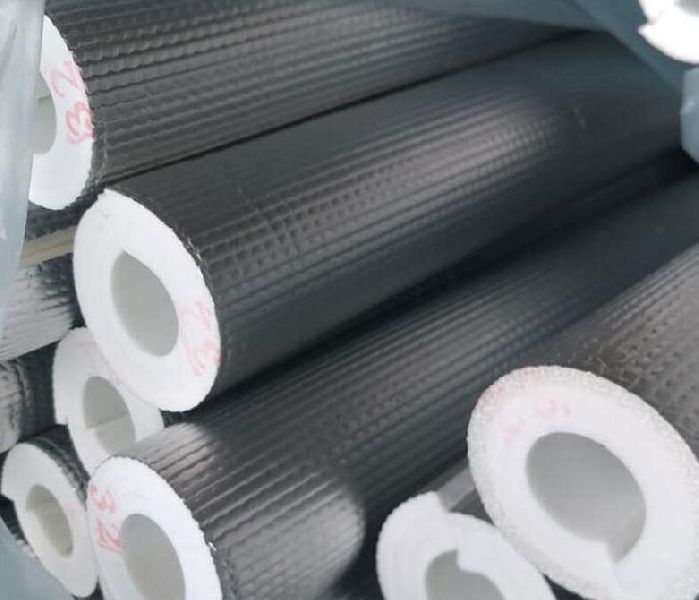

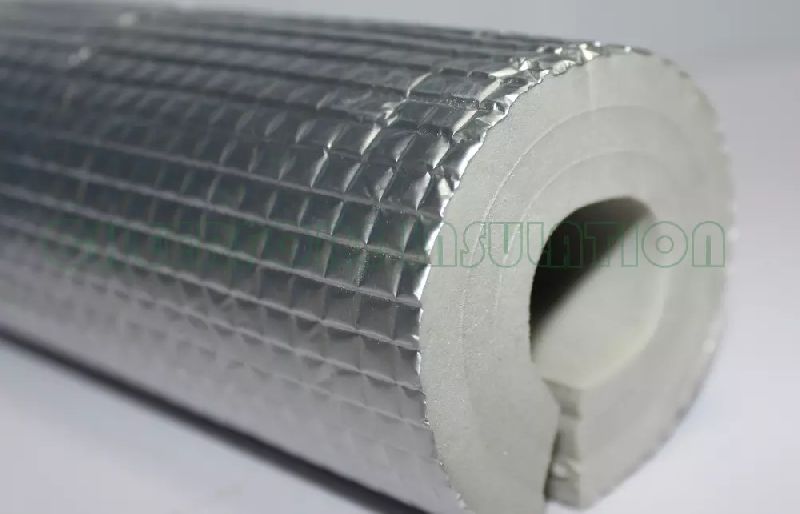

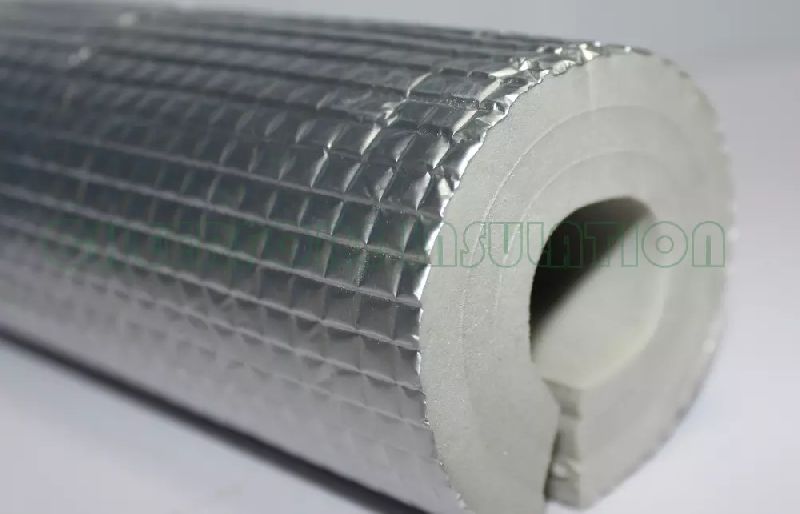

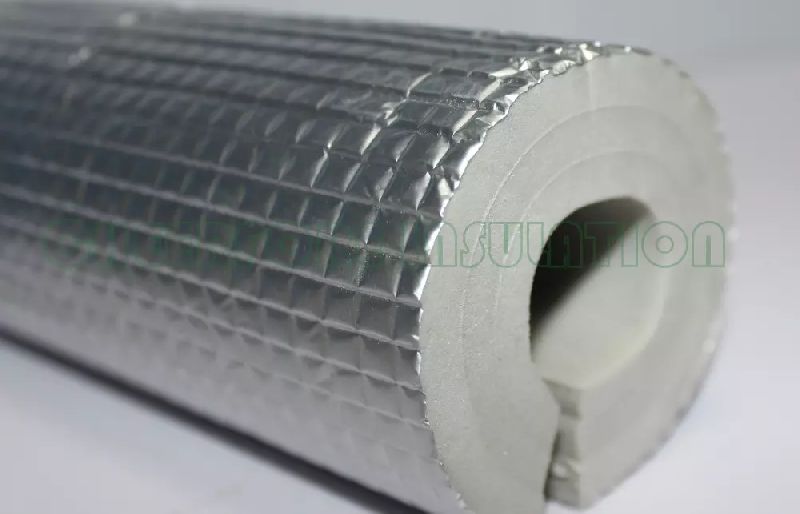

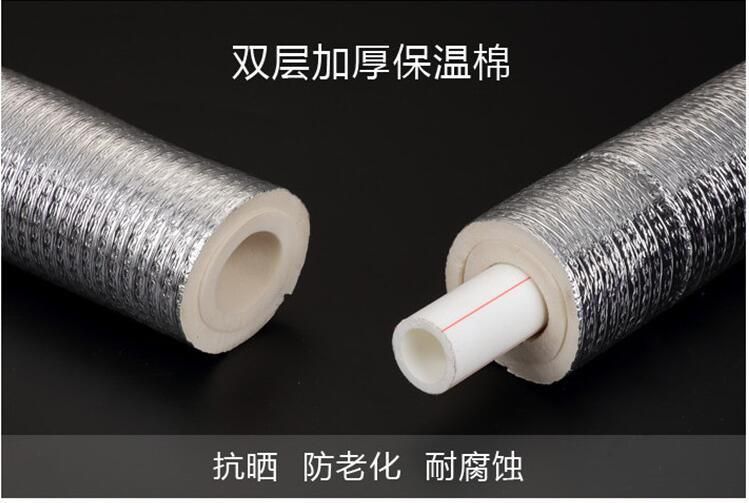

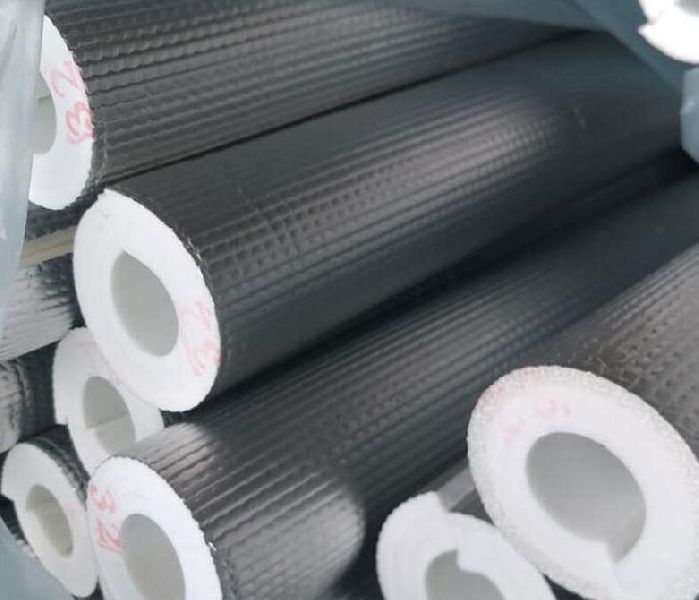

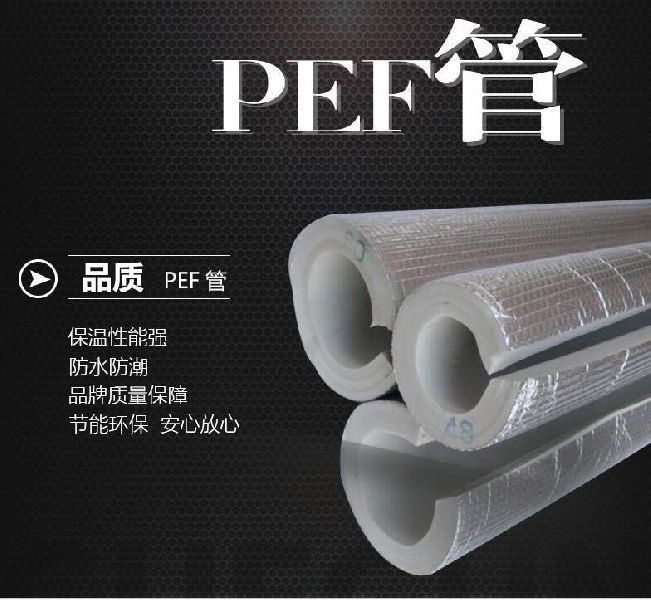

Contact SupplierProduct Description : PE Foam tube which is known as Polyethylene Foam is a firm and closed cell foam with cross-linkage that provide more rigidity. PE Foam Sheet is very hard to recover to original shape after compression and doesn't spread compressed energy easily. Due to heat-absorbing and shock-absorbing properties, this closed cell foam is great to weaken the effect of vibration. Ideally suited as packaging material for long-distance transportation. Polyethylene (PE) foam, full closed cell structure, is made from LDPE, flame retardants, etc., and free from PVC, gives out low smoke and non-toxic matter.

CF PE Foam Tube Characteristics:

PE FOAM with Embossed Aluminum Foil Advantages:

PE Foam Tube Main Application:

| Item | Unit | Testing Standard | Parameters | |

|---|---|---|---|---|

| Surface Density | Kg/m3 | GB/T6343-1995 | 28-45 | |

| Burning Grade | -- | GB8624-1997 | B1 | |

| Burning Performance | Oxygen Exponent | % | GB8624-1997 | 32.8 |

| Smoke Density | % | GB8624-1997 | 50 | |

| Heating Conductivity coefficient | Average Temperature 10ºC | W/(m·k) | GB3399-1988 | 0.0327 |

| -20ºC | -- | |||

| 0ºC | ||||

| 40ºC | ||||

| Moisture Penetration | Coefficient | G/(m·s·pa) | GB/T 17794-1999 | ≤2.4×10-10 |

| Moisture Resistance | -- | GB/T 17794-1999 | 8.1×102 | |

| Water Absorption in Vacuum | g/cm3 | GB/T 1034-86 | 0.0019 | |

| Dimension Stability | % | GB/T8811-1988 | 0.66 | |

| 70ºC ±3ºC,48h | ||||

| Rebound Rate after Compression | % | Q/(GZ) HD1-2003 | 96 | |

| Ripping Intension | N/cm | GB/T 10808-1989 | 3.3 | |

| Ozone endurance Ozone Suppressor202mPa,200h | -- | GB/T 17794-1999 | No Chaps | |

| Aging Resistance(150h) | -- | GB/T 17794-1999 | No Wrinkle | |

| No Crack | ||||

| No Pinhole | ||||

| No Distort | ||||

| Temperature Range | ºC | -50~+90 | ||

| Tube Size | Thickness of Series | Standard Length | ||||

|---|---|---|---|---|---|---|

| C | D | E | ||||

| inch | DN diameter | Tube Diameter | (mm) | (mm) | (mm) | |

| 43467 | DN15 | 20 | 16 | 18 | 23 | 1.0m/pc or 1.2m/pc |

| DN15 | 22 | 16 | 18 | 23 | ||

| 43528 | DN20 | 25 | 16 | 18 | 24 | |

| DN20 | 28 | 16 | 18 | 24 | ||

| 1 | DN25 | 32 | 16 | 20 | 24 | |

| DN25 | 35 | 16 | 20 | 24 | ||

| 1.1/4 | DN32 | 38 | 16 | 20 | 26 | |

| DN32 | 42 | 16 | 20 | 26 | ||

| 1.1/2 | DN40 | 45 | 16 | 22 | 26 | |

| DN40 | 48 | 16 | 22 | 26 | ||

| 1.3/4 | DN45 | 51 | 16 | 22 | 26 | |

| 2 | DN50 | 57 | 20 | 23 | 28 | |

| DN50 | 60 | 20 | 23 | 28 | ||

| 2.1/2 | DN65 | 76 | 20 | 23 | 28 | |

| 3 | DN80 | 89 | 20 | 25 | 30 | |

| 4 | DN100 | 108 | 25 | 30 | ||

| DN100 | 114 | 25 | 30 | |||

| 5 | DN125 | 113 | 26 | 35 | ||

| DN125 | 140 | 26 | 35 | |||

| 6 | DN150 | 159 | 28 | 35 | ||

| DN150 | 168 | 28 | 35 | |||

| 8 | DN200 | 219 | 30 | 40 | ||

| 10 | DN250 | 273 | 30 | 40 | ||

| 12 | DN300 | 325 | 30 | 40 | ||

| 14 | DN350 | 371 | 30 | 40 | ||

| DN350 | 377 | 30 | 40 | |||

| 16 | DN400 | 426 | 33 | 42 | ||

| 18 | DN450 | 480 | 33 | 42 | ||

| 20 | DN500 | 530 | 35 | 45 | ||

| 24 | DN600 | 630 | 35 | 45 | ||

| Thickness Tolerance (mm) | ±0.75 | ±1.5 | ±1.5 | |||