Company Information

Ask for more detail from the seller

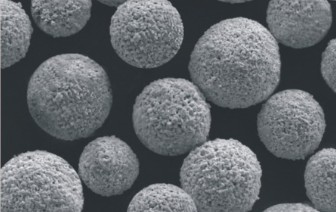

Contact SupplierWe offer hvof & thermal spray tungsten carbide powders. Hvof & thermal spray tungsten carbide powders feature

with high hardness, great wear-resistant, erodent-resistant and concussion-resistant

with well-proportioned grain, great apparent density and high density.

with good capability of spray-welding

hvof spray (high velocity oxy-fuel coating spraying)

in the hvof process, powder is introduced axially into a chamber in which a gas flame is constantly burning under high pressure. The exhaust gas exits through an expansion nozzle which produces a high velocity gas stream. The powder particles are heated in this gas stream and transferred by it with kinetic energy to the surface of the work piece, forming a dense coating with excellent bonding properties.

Due to the moderate transfer of heat to the powder particles and to the work piece, which remains relatively cool, there is little metallurgical change to either the sprayed material or work piece.

hvof & thermal spray tungsten carbide powders particle size

-45+15μm -45+11μm -45+5μm -106+45μm -125+31μm -63+11μm -53+11μm

hvof & thermal spray tungsten carbide powders packing:

5 poundsbox (11x11x7cm), 5 boxes in one carton(13*13*37cm)

10 poundsbox (11x11x7cm), 5 boxes in one carton(13*13*37cm)

50 pounds barrell(30x30x28)

100 poundsbarrel(30x30x28)

hvof & thermal spray tungsten carbide powders quality control

all raw material are tested in terms of density, hardness and t.r.s before use.

there are strict inspection on process and final products.

every batch of product can be traced.