Company Information

Ask for more detail from the seller

Contact SupplierTHERMIC FLUID HOT OIL PUMP (Air Cooled, Single Stage, Horizontal, End Suction Pump)

We are world’s largest manufacturer of thermal fluid pumps used to move heat-transfer oils at high temperatures. Our thermic fluid pump is also referred to as a hot oil circulating pump. It is the finest option for better leakage control and energy savings.

Our thermic fluid pump has been designed to circulate hot oil and high-temperature liquid, which makes

this pump more suitable for applications in heat transfer plants.

The air-cooled pump designed by FITZER represents the highest quality and most effective air-cooled industrial pump in the market.

FITZER is India's leading exporter of industrial pumps, exporting a wide range of top-quality products to industries worldwide. We export our products to Turkey, Saudi Arabia, Dubai, Thailand, Australia, Sri Lanka, Bangladesh, Oman, South Africa, Iraq, and many other countries.

TECHNICAL SPECIFICATIONS:

Operating Range:

Capacity: up to 1100 m3/hr

Head: up to 150 Meter

Pressure: up to 15 kg/cm2

Size: 32 mm to 125 mm

Speed: up to 3500 rpm

Temp: up to 350 C

M.O.C.: Grey Cast Iron, Cast Steel, Alloy Cast Steel, S.S 304, S.S 316, etc.

PUMP FLANGES

Discharge Flanges: DIN 2533 – PN 16

Suction Flanges: DIN 2533 – PN 16

DESIGN FEATURES:

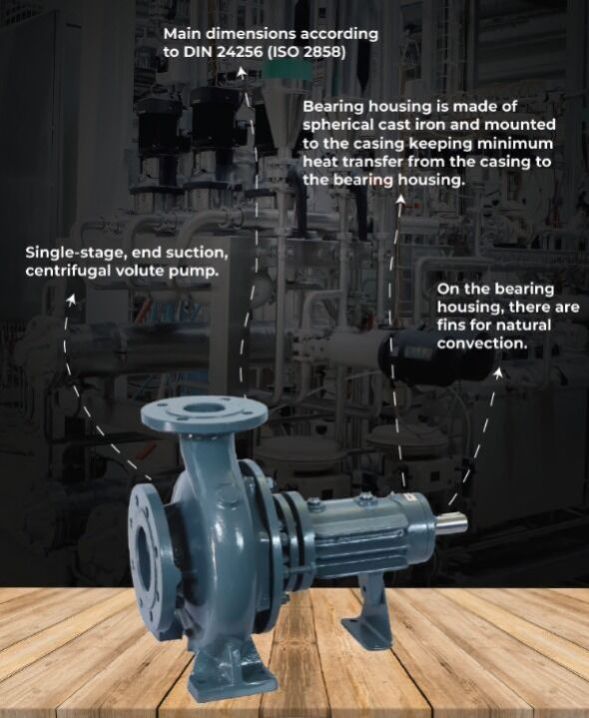

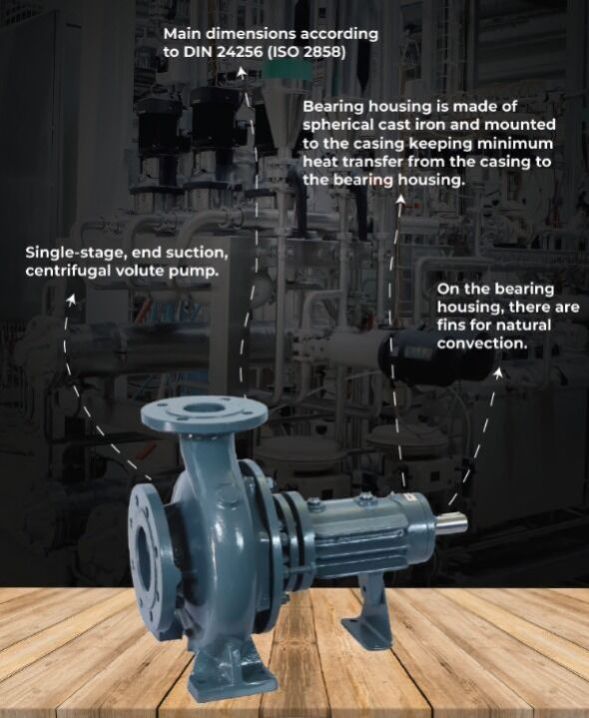

Main dimensions according to DIN 24256 (ISO 2858)

Single-stage, end suction, centrifugal volute pump.

Bearing housing is made of spherical cast iron and mounted to the casing keeping minimum heat transfer from the casing to the bearing housing.

On the bearing housing, there are fins for natural convection.

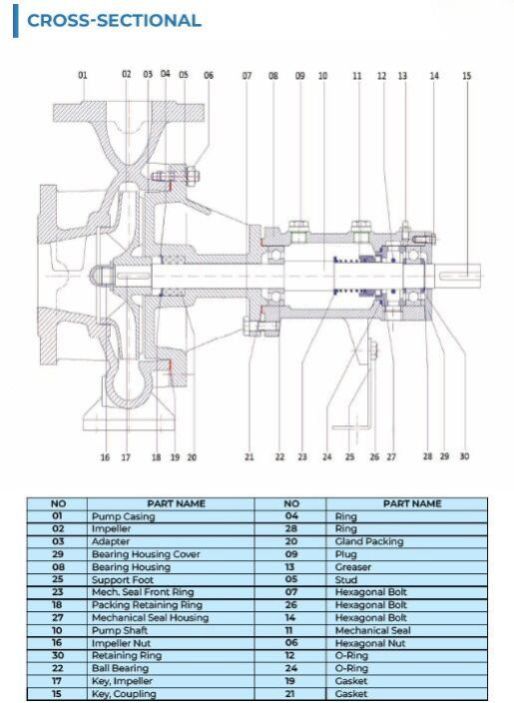

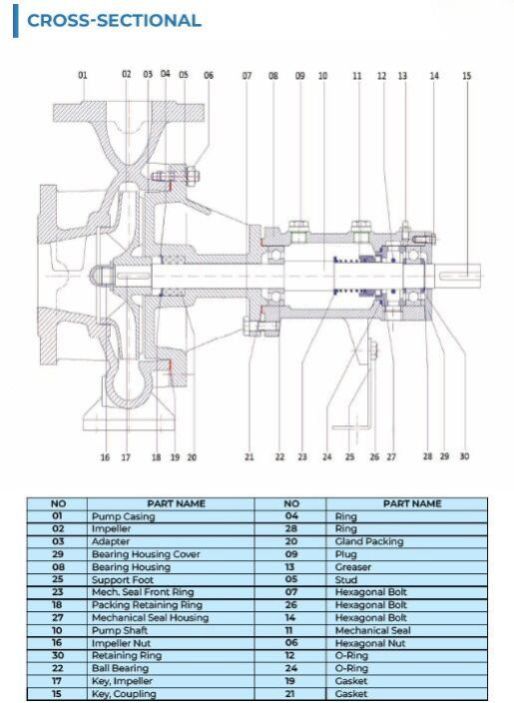

There is a thermal-resistant soft packing seal behind the impeller.

It slows down the leakage and prevents the pumping to be stopped if there is mechanical seal damage.

First bearing is on the impeller side and lubricated with a working medium.

Second bearing is on the coupling side and lubricated with grease.

The shaft is designed according to the minimum heat transfer criteria.

The mechanical seal stands between two roller bearings and is close to the roller bearing on the coupling side. This gives the mechanical seal a longer working life since it is in a low-temperature region.