Listing ID #4863239

Company Information

Ask for more detail from the seller

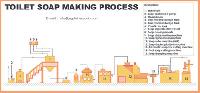

Contact SupplierADHISAKTHI is well experienced to design and deliver toilet soap manufacturing facility in a state of the art standard.

Following machineries are supplied to perform individually or as a complete plant.

OPTIONS : FULLY AUTOMATIC TOILET SOAP PLAT

MECHANIZED TOILET SOAP PLANT

BASIC PLANT

TOILET SOAP PLANT FINISHING LINE:

SALIENT FEATURES OF MECHANIZED PARTIAL AUTOMATIC TOILET SOAP PLANT: