Company Information

Ask for more detail from the seller

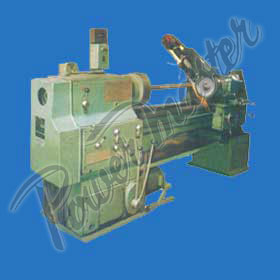

Contact Supplier"POWER MASTER" Tool Post Grinding Machines are specially designed for mounting on the saddles of medium or heavy duty Lathe Machines and are most useful for grinding and polishing between centres of all types of shafts and other cylindrical components such as Rubber Rollers,engraved printing and metal printing rollers, Stainless calender rollers, M.G. Cylinders for the Paper Mills, chromium plated rods and various other applications.

The Machine comprises of a totally enclosed fan cool electric drive of suitable horsepower specially designed to receive Belt grinding arm on it. Contact wheel is also mounted on the shaft extension of the drive. The arm is suitable for standard sizes of abrasive belts and can be rotated at all angles with respect to the drive. This facilitates the adjustment of the belt angle with respect to the job. Belt tensioning is done by means of a telescopic spring whereas a hand wheel is used for tracking.

For intense stock removal (rough grinding) the Tool Post Belt Grinder should be mounted on the tool post in such a way that the abrasive belt is pressed over the contact wheel against the workpiece. The contact wheel to be used should be medium or hard and serrated with belts of rough grits (Grit 36 or 60). For very light material removal (finishing) either a soft contact wheel may be used or finishing may be done on the slack of belt and belts of fine grits are to be used (Grit 80, 120 & Finer) .

| S.No | K.W. | H.P. | Model | RPM | Centre Height | Belt Size Width x Length | Contact Wheel Dia x Width x Bore | Motor Base Front x Size |

| 1 | 0.75 | 1.0 | TPBG/100/1 | 1440/2800 | 100 | 50 x 2000 | 250 x 50 x 25.4 | 170 x 195 |

| 2 | 1.5 | 2.0 | TPBG/100/2 | 1440/2800 | 100 | 50 x 2000 | 250 x 50 x 25.4 | 170 x 195 |

| 3 | 2.2 | 3.0 | TPBG/100/3 | 1440/2800 | 100 | 50 x 2000 | 250 x 50 x 25.4 | 170 x 195 |

| 4 | 3.7 | 5.0 | TPBG/522/5 | 1440 | 140 | 50 x 3500 | 450 x 75 x 38.1 | 240 x 280 |

| 5 | 5.5 | 7.5 | TPBG/522/7.5 | 1440 | 140 | 75 x 3500 | 450 x 75 x 38.1 | 240 x 280 |

| 6 | 7.5 | 10.0 | TPBG/722/10 | 1440 | 150 | 75 x 3500 | 450 x 75 x 38.1 | 250 x 275 |