Company Information

Ask for more detail from the seller

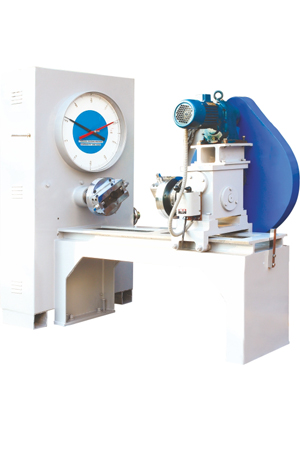

Contact SupplierFeatures:

Unique "Talon -Claw" Grips for Round and flat speciemens ( optional at extra cost) Torsional Speed of 0.1/0.2 RPM (optional at extra cost) Torque Compensated Motors Maintenance Free gear Box Auto Range selection with Range selector wheel (optional at extra cost) 3 or 4 Torque Ranges for higher Accuracy (optional at extra cost )

It is desighned for conducting torsion and twist tests on various materials.Torque measurement is by an electronic torque transducer for direct display of torque.Torque is applied to speciemen by geared motor through gear box.The accuracy of the torque indication is +_ 1% of the true torque.The complete system is hydraulicly damped for vibration free loading.

Main applications:

This kind of testing machine is used for the torsion test foir all kinds of materials,by imposting a torque.

There are two testing methods

Automatic Testing :- Turn the hand wheel until the test rod breaks.The testing machine will automatically test the yeild M1 and the maximum torque M2.

Manual testing :- Choose the test angles and tropes of any 9 points during the testing perios and recors them.

Able to petreeive or print testing results after the test

It is mainly suitable for materials labs of scientific resarch department.colleges or universities and industrial enterprises to test the mechanical properties under torsion condition

Main Technical Specification:

Item Names specification

Max.test torque (N.m) 200

Min.reading of torque (n.m) 0.02

Torque measurement angke (N.m) 20-200

max reading of tosion angle 9999.95

Min.reading of torsion angle (o) 0.5

Relative error of torque indications

| Model | TT-6 | TT-10 | TT-20 | TT-50 |

| Capacity Kg-m | 6 | 10 | 20 | 50 |

| Torsion speed | Fixed | Fixed | Fixed | Fixed |

| Direction | One way | Reserve | Reserve | Reserve |

| Gear Motor 3ph (hp) | 0.5 | 0.5 | 0.5 | 0.5 |