Company Information

Ask for more detail from the seller

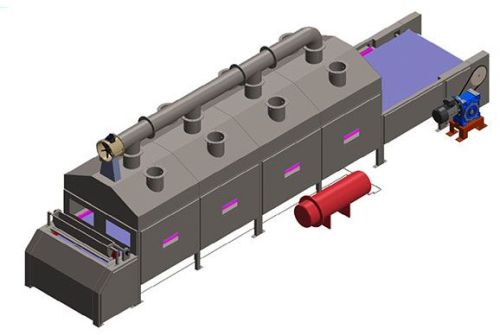

Contact SupplierIn Refractive Window Drying technology, drying of product is done using a thin, transparent infrared film which eventually forms a “window” for drying. The thin film is conveyed above a heated water tank which assures very low-temperature drying with rapidity, with all modes of heat transfer such as conduction, convection and radiation. As the product dries, however, the infrared “window” closes, effectively limiting heat transfer to the product to conduction.

RW Drying is a new indirect contact drying technology that uses circulating hot water below boiling point as an effective heat transfer medium under atmospheric pressure. The energy or heat losses from the water to its surroundings occur by conduction, convection and radiation resulting in faster drying.

During a trial, the process dried raspberry puree from 92% moisture to 2-4% moisture in just five minutes. The dried product had high bulk density. Product quality shows good results as compared to drum drying, freeze-drying, spray drying, tray drying, etc. while being extremely energy efficient.

Advantages:

Colour, Flavour and Nutrients of the product is maintained

Microstructure of the product is smooth with Uniform Thickness

Low loss of Anthocyanin from the product

Higher Bulk density and Low Porosity of the Product

No Sulphites or Additives are needed to Dry

Low Product Temperature

Short Drying Time

Energy Efficient Drying System

Low Capital Expenditure compared to other Dryers