Company Information

Ask for more detail from the seller

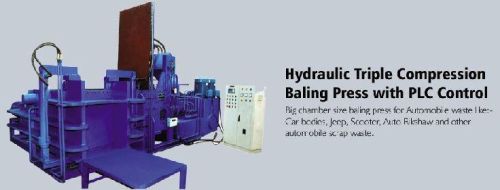

Contact SupplierBig chamber size baling press for Automobile waste like:-

Car Bodies, Jeep, Scooter, Auto Rikshaw and other automobile scrap waste.

Our Triple Compression Baling Presses have a reputation of excellence for their quality, workmanship and reliability Since 1984. These presses are available in Triple Compression. They are suitable for all types of ferrous and non-ferrous light metal scrap material such as stainless steel, M.S. scrap, aluminium, brass, copper and other industrial tin sheets..

Salient common features:

The production capacity ranges from 0.5 ton to 10 tons per hour and more as desirable

The operation of press is done by hand lever, semi automatically & fully automatically through PLC Programmable Logic Control. PLC provided in our baling presses are of international standards offering maximum production flexibility

Shearing blades and replaceable wear-resistance plates can be provided for the long life of the feeding chamber

All parts contacting the scrap is covered with 40 HRC hardness, 10 mm thickness having hardened sheet metal offering lengthened machine life

Hydraulic pistons are designed to work under hard conditions and installed with the most suitable sealings

In these presses there are 3 compressing systems. After the scrap is put in charging box, first lid cylinder operates and compresses the scrap from top position. It also closes the charging box, secondly main ram moves forward and thirdly side cylinder comes forward pressing the scrap to required size and weight. Thus making the final bale. Bale is pushes out by ejector cylinder.

All machines are rigorously tested prior to the delivery