Company Information

Ask for more detail from the seller

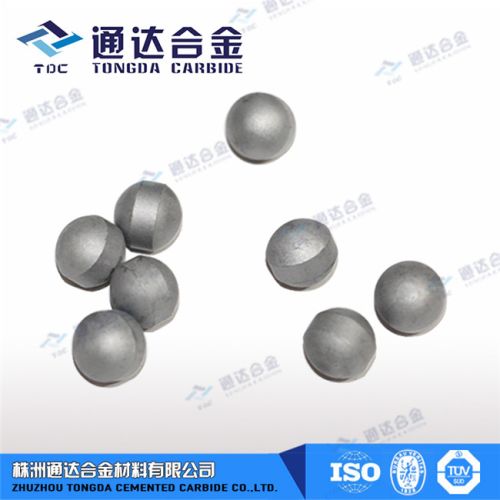

Contact SupplierTungsten carbide bearing ball main ingredient is tungsten-cobalt alloy (wc-co), made of a special working conditions tungsten carbide bearing ball, has high temperature, abrasion resistance, and excellent corrosion resistance and other characteristics, and in high vacuum magnetically shielded tungsten carbide bearing ball achieved certain results. In addition, due to the tungsten carbide bearing ball with a variety of special properties: such as good wear resistance, red hardness, high strength and high hardness, making it the ideal choice for ball bearings.

Diameter selection of tungsten carbide bearing ball

ball bearings are standard components of the support shaft, which has a small friction, high efficiency, compact structure, easy maintenance and so on. Bearing clearance (refers to the maximum distance in the absence of load, between the bearing inner and outer ring can move) dynamic load has a significant impact on bearing life, temperature, noise, rated. Usually at the operating temperature of the ball bearing clearance should be close to 0; for large shocks, heavy-duty environment, should be used in a large bearing clearance; for high running accuracy, sound demanding, should be used in smaller bearing clearance. Tungsten carbide bearing ball diameter size is also directly related to the clearance size. Internal clearance is generally non-adjusted bearings shall be subject to professional option, by selecting the appropriate clearance levels and cooperate in order to ensure the normal operation of the bearing. Clearance of the bearing capacity of the bearing, slewing sensitivity, life, vibration characteristics have an important impact on the current traffic control clearance method is matching the right size ball during assembly, through multiple assembly and disassembly, matching up measure axial clearance to meet the requirements.