Company Information

Ask for more detail from the seller

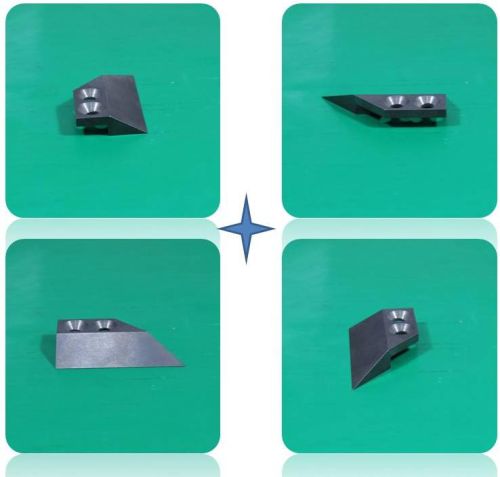

Contact SupplierWe are offering tungsten carbide insert

as we all know that tungsten carbide inserts has at least three cutting parts, and when one of the cutting edge is damaged, users can adjust to another edge for manufacturing, therefore, the carbide inserts are also called tungsten carbide indexable inserts. Tungsten carbide indexable inserts are well known for its durable superiorities, and for finding inserts of long time serive life, tungsten carbide indexable inserts become one of the mostly popular inserts among users.

Usage: wood-cutting tools, clamped inserts, milling & turning inserts, etc.

Feature: high precision and high reliability, durable superiorities

tungsten carbide inserts for metal cutting

tungsten carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger tipped tool whose shank is made of another material, usually carbon tool steel. This gives the benefit of using carbide at the cutting interface without the high cost and brittleness of making the entire tool out of carbide. Most modern face mills use carbide inserts, as well as many lathe tools and endmills. In recent decades, though, solid-carbide endmills have also become more commonly used, wherever the application's characteristics make the pros outweigh the cons.

Mining and tunneling cutting tools are most often fitted with cemented carbide tips, the so-called "button bits". Only man-made diamond can replace the cemented carbide buttons when conditions are ideal, but as rock drilling is a tough job the cemented carbide button bits remain the most used type throughout the world.