Listing ID #4798543

Company Information

Ask for more detail from the seller

Contact SupplierTo descale mild steel plate & structurel section prior to painting.

"ABRABLAST" has a wide range of Airless Shot Blasting Machine Tunnel Type With numbers of Blast Wheels to suit the Job Size and according to Productin output required. This is the mostly used to Blast Clean long structural members, channels, angles, gratings, pipe fabricated components etc. for large production output for removing rust and to achieve superior quality (approx. Sa2/Sa2.5 SSPC standaerds) finish after blast cleaning prior to painting.

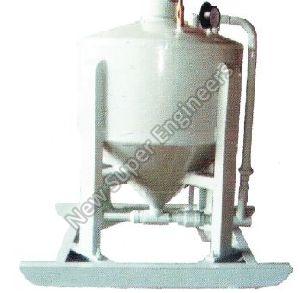

The opening of the tuunel & required number of blast wheels depends upon the structure of job for attaching homogeneous finish.Major assemblies of the machine are blast wheels for giving high production output, roller conveyor for job conveyoing & media recovery consists of bucket elevetor , screws conveyors , rotary screen separators , abrasive storage hopper etc. & pulse jet type dust collectors is less than 10 miiligram per cubic meter.

the works pieses is to be placed as far as possible in the centre of the guides of rolers on in feed conveyor when the rollers are not in rotating. The possition of work pieses is in such a way that it can rolled easily hrizontal as shown in phtograph , to avoid the accumulation of shots . After then it passes throgh entry vestibule tunnel and then enters into the blasting chambner for blast clean process . If the prefabricated structure can not be rolled on the rollers then it has to be kept either on predesinged fixture or a trya enabling it to travel & pass through the blast cabinet.

Blast wheel stations are aranged strategically around and located on the top of cabinet propels abrasive on the rolling works pieces. The blower arrangment continuely blow- off abrasive accumlated on the top side of the work piece . After shot blasted homogeneously finished all around air washed work pieces rolls out from exit vestibules tunnel to the out feed conveyor rollers , from where it is to be unloaded manually . The operatons of squence is details programmed for ease of operaton and to achive the required performance.

Tunnel Type Shot Blasting Machine

Stone Shot Blasting Machine

Structure Shot Blasting Machine

Paver Block Shot Blasting Machine

Rod Bar Cleaning Shot Blasting Machine

Pipe Cleaning Shot Blasting Machine

Fabricated Structure Shot Blasting Machine

Stone Texuring Shot Blasting Machine

Abrablast Equipment Company is a well-known name from Jodhpur (Rajasthan) that is recognized for its strong foothold in the manufacture and export business. We are one of the specialized manufacturers, exporters, and suppliers of the modernistic dust collector and shot blasting machine. We are also engaged in providing services with our services being annual maintenance cost, blaster machine installation, and blaster machine repair. We have been manufacturing and marketing all types of shot blasting machine, their spares, and abrasive media.

Established in the year 2010, Abrablast Equipment Company has been successfully catering to global needs with its premium products and world-class services. Today, we are serving the patrons across India, the Middle East (Oil and Gas Industries), and Australia.

What We Offer

Our product range includes:

Our facility is equipped with advanced machinery and tools, required to manufacture the shot blasting/painting/baking/ventilation equipment. We have a good team of design, production and quality control as well as the marketing department to ensure quality product at the earliest delivery.