Company Information

Ask for more detail from the seller

Contact SupplierMORE STABLE:

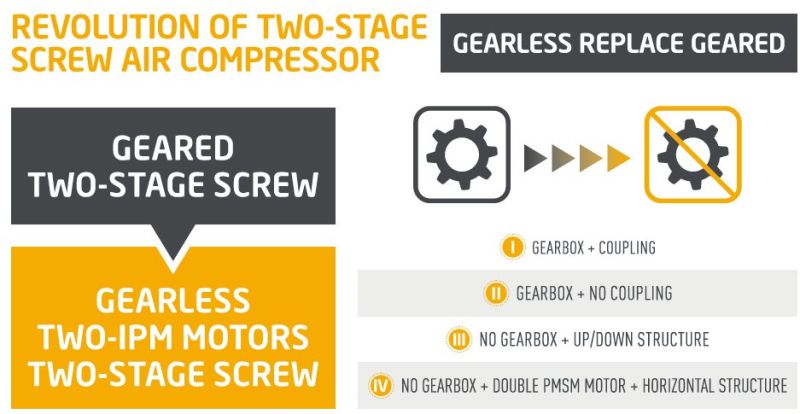

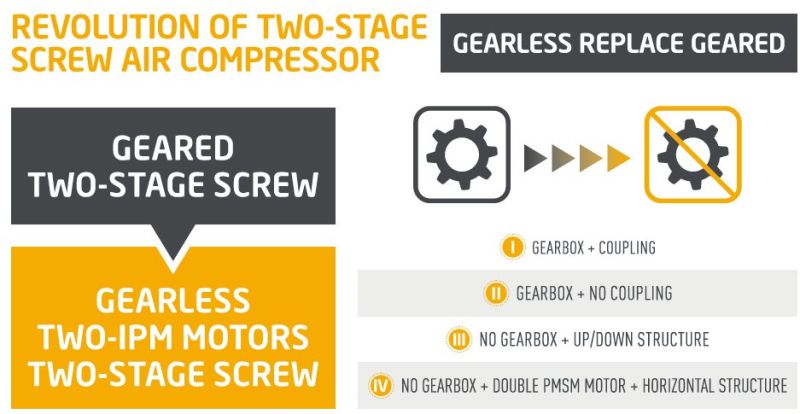

IPM motor and air end are connected with one-shaft. Without gear: no gear pitting, no broken-teeth.

Less damage to electrical equipment

100% to prevent oil leakage. Without leak troubles.

The high-performance permanent magnet materials.

The specialized corona-resistance enameled wire is applied to stator coil.

Oil is effecting on the gear all time. Underling the long-term running in variable speed, the gear will have pit-ting, even teeth broken.

Independent air cooling.

Don’t need to rely on the compressor cooling system.

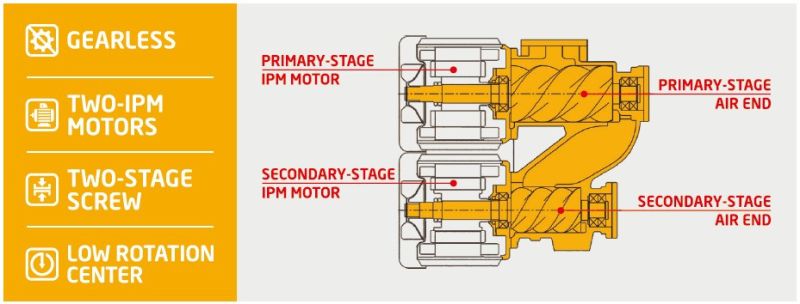

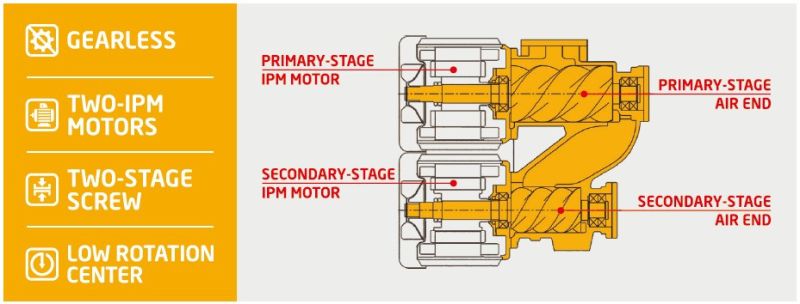

Two independent IPM motors directly drive two stage air end.

One-shaft structure, without coupling danger.

MORE SAVING:

SLPM is driven by two independent IPM motors, intelligent control. During operation, by control-ling the pressure between the two stage. The optimal rotating speed of two air outlet are auto-matically calculated to attain the optimal effi-ciency with optimal compression radio of match-ing and balance, allowing compressor always under optimal operation condition.

SPLM FOCUS ON THE TOP EFFICIENCY DURING PRACTICAL USE THE RANGE OF FREQUENCY CONVERSION UP TO 30% TO 100%

MORE EFFICIENCY:

SLPM is with motor, excellent performance.

Under low frequency, low speed, it can still keep high efficiency.

Compared with geared two-stage, TRANSMISSION EFFICIENCY ONLY REACHED 97%

One shaft structure, gearless , without coupling. 100% TRANSMISSION EFFICIENCY.

MORE COMFPRTABLE:

MORE COMPACT:

Smaller motor size, one shaft structure can save more space.

Motor IPM (Internal permanent Magnet) Motor IP54