Company Information

Ask for more detail from the seller

Contact SupplierCrushing Mills

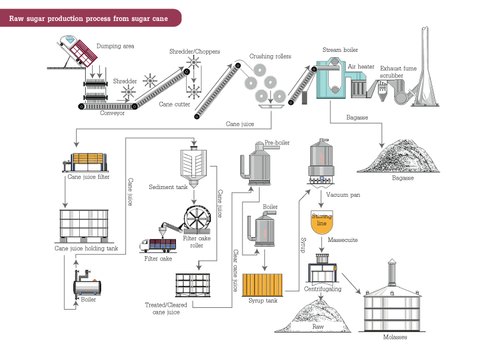

After tipping the cane passes through a shredder, which reduces the billets of cane to a fibrous mass. The shredded cane then passes through a series of mill tandem to extract as much cane juice as possible. Most of the crushing mills are driven by electric motor. The juice from the first crushing mill is analysed in the laboratory for sugar content (CCS). Payment to growers is based on weight of cane and CCS value

Steam Generating Plant

The fibre remaining after the cane has passed through the milling train is called "bagasse". Bagasse is used as fuel for the boiler plant, which provides steam to power the entire factory including our electricity generating turbines. Bagasse is also stored for use in the lead up to the start of the crushing season and when wet weather disrupts harvesting operations. This makes our factory virtually independent of external energy needs during the crushing season

Clarification

The cane juice, as delivered from the milling tandems, contains some soil and other undesirable impurities. To remove these, the juice is heated and lime is added to settle the unwanted material. The impurities settle out in the clarifier and then go to the rotary vacuum filters, which filter out any remaining juice. The filter mud from the vacuum filters is rich in nutrients and is recycled back to cane fields. Clear amber coloured clarified juice containing about 15% sugar is decanted from the clarifiers to the evaporators

Evaporation

The clarified juice is concentrated to thick syrup by boiling off water in the evaporators. The juice passes continuously from vessel to vessel until it is concentrated to syrup containing approximately 70% sugar. The evaporators are operated under vacuum and in "multiple effects" configuration whereby the vapour space of one vessel is connected to the heating surface of the next throughout the set. This gives maximum efficiency in evaporation and steam usage. Boiling under a vacuum is very energy efficient because the boiling point of the liquid is much lower than at normal atmospheric pressure

Pan Stage

At the pan stage the syrup from the evaporators is converted to crystal sugar. A charge of syrup is taken into a vacuum pan and again boiled under a vacuum. A quantity of very fine “seed” crystal is introduced. As water is evaporated fresh syrup is added and sugar is deposited on the seed crystal. This process continues until the crystals have reached the desired size (approx. 1 mm square). The resulting semi liquid mass of sugar crystals and molasses is called ‘massecuite'.

Centrifugation

Sugar crystals are separated from the syrup in the centrifugals. The centrifugals are perforated metal baskets spun at high speed by an electric motor. While the sugar is spinning in the baskets it is given a short burst of hot water to help wash the sticky molasses off the sugar crystals.

Sugar Dryers

Sugar has to be dried and cooled to precise levels to enhance its storage life. This is done in the sugar driers. Evaporation of excess water from the surface of the crystals results in the desired cooling of the sugar. In the generally wet conditions we use large air-conditioning units to provide the cool dry air to the sugar driers. The dried and cool sugar is now ready for shipment.