Company Information

Ask for more detail from the seller

Contact SupplierProduct Description

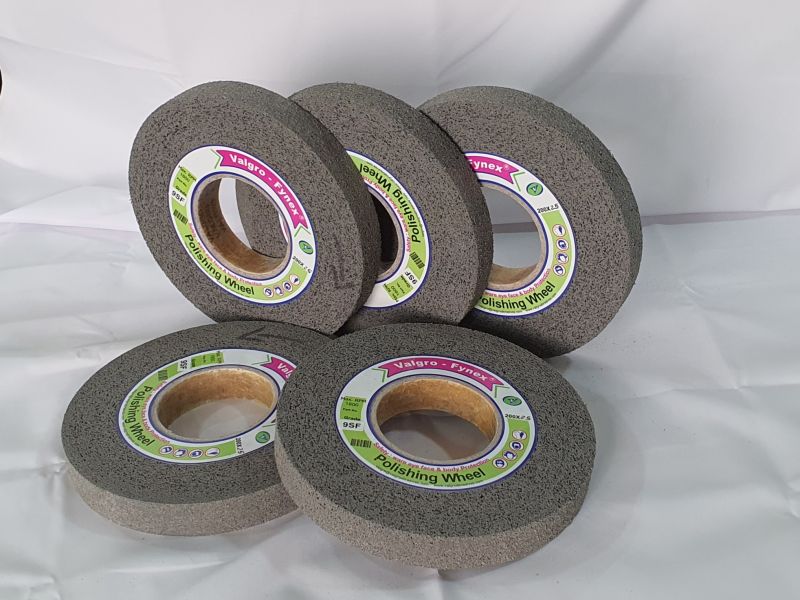

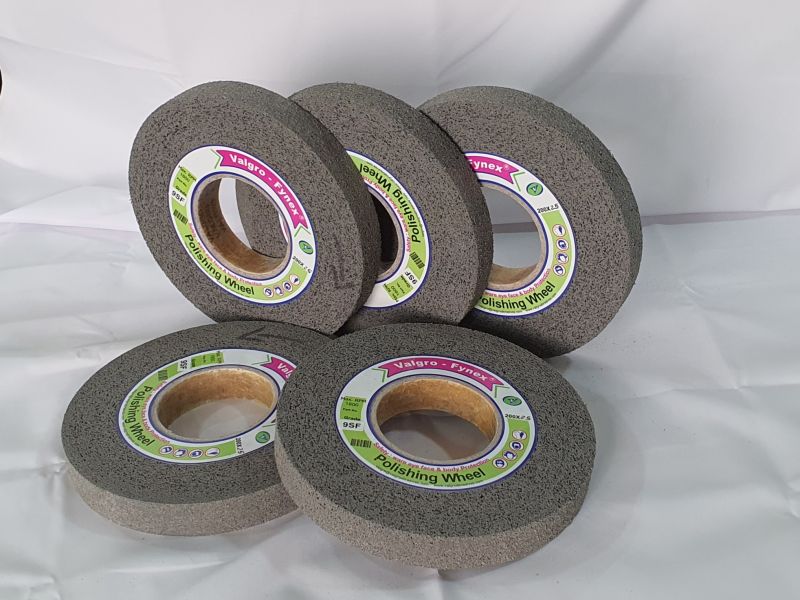

The Valgro Cut N Polish EXL Deburring & Finishing Wheel is a high-density, non-woven abrasive wheel engineered to rapidly remove burrs, clean edges and deliver a polished surface finish on metals, composites and glass. It’s ideal for laser-cut, punched, formed or machined parts where consistent surface quality and edge condition are critical.

Overview

This wheel combines deburring, edge-radius formation and polishing in one operation. It features a solid, dense construction and conformable design to maintain effective contact even on complex-shaped parts or robotic end-of-arm tools. Typical users include manufacturers of aerospace components, medical instruments, decorative hardware, aluminium extrusions, and stamped/fabricated metal parts.

Key Features

Solid, dense non-woven construction designed for high consistency and long life

Conformable design to maintain contact with contoured surfaces without gouging or undercutting

Suitable for a wide range of materials including metals, composites and glass

Engineered for smooth wear to keep fresh abrasive exposed continuously

Effective especially on heat-sensitive substrates thanks to minimal heat build-up

Benefits

Achieves deburring and finishing in one step — reducing process time, labour and equipment cost

Delivers a smooth, polished finish that enhances aesthetics and reduces secondary polishing

Minimises risk of distortion, gouging or surface damage thanks to conformable, controlled removal action

Optimises productivity and tool life with controlled wear and consistent results

Supports complex part geometries and automated finishing systems

Typical Applications

Deburring and finishing of laser-cut, punched or stamped metal parts

Edge finishing on machined components such as blades, housings, fasteners, extrusions

Cosmetic surface preparations for architectural hardware, medical instruments, aerospace components

Finishing operations where one tool must accomplish burr removal, smoothing and surface polish