Company Information

Ask for more detail from the seller

Contact SupplierProduct Description

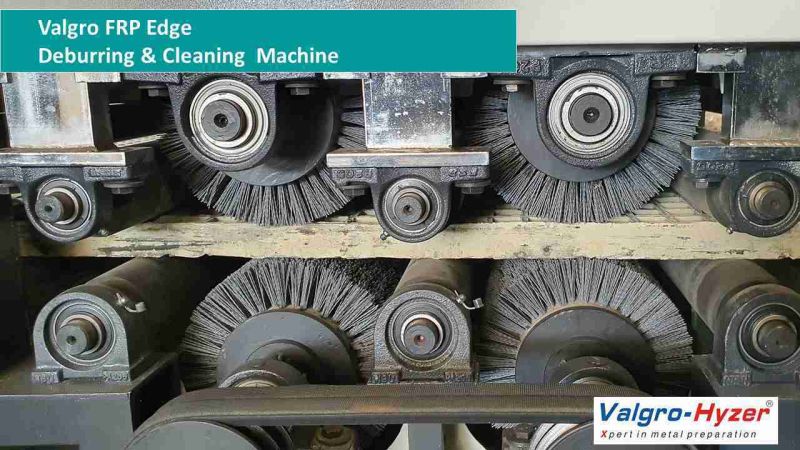

The Valgro Grating Edge Deburring Machine is engineered for efficient and reliable removal of burrs and rough edges on grating panels — whether FRP (fibre-reinforced plastic) or metal. Designed to deliver uniform, safe, and finished edges, this machine ensures panels meet quality, appearance and safety standards.

OverviewGrating panels often emerge from cutting or fabrication processes with sharp edges, exposed fibres or unfinished surfaces which can impair durability or increase risk of injury. The Valgro Grating Edge Deburring Machine addresses these challenges by providing a dedicated edge-finishing solution capable of smoothing, rounding and cleaning panel edges with speed and consistency. The system is built to integrate into production lines for high-volume output while maintaining precision.

Key FeaturesSpecialized for edge finishing of grating panels (metal or FRP) to remove burrs, exposed fibres and sharp edges

Robust construction suited for industrial use and continuous operation

Uniform edge treatment for improved safety (no sharp edges) and improved downstream performance (coating, installation)

Suitable for high throughput: designed to handle panel feed, edge deburring and cleaning in an efficient workflow

Improves panel finish quality and supports better edge integrity / fibre containment in FRP or better edge condition in metal grating

Enhances product safety and reduces risk of injury from sharp or unfinished edges

Improves aesthetics and finishing quality – smoother edges, fewer defects

Reduces labour cost and time compared to manual edge finishing methods

Supports coating, installation, or assembly by delivering panels with ready-finished edges

Gives better durability (especially for FRP gratings) by limiting exposed fibres or poorly finished edges

Deburring and edge finishing of FRP gratings used in flooring, platforms, walkways or industrial sections

Finishing metal grating panels or architectural grating panels where edges must be smooth and safe

Fabrication lines where grating panels are produced at scale and require consistent edge finish for installation or coating

Construction, marine, petrochemical, industrial flooring sectors where grating safety and finish matter