Listing ID #5644086

Company Information

Ask for more detail from the seller

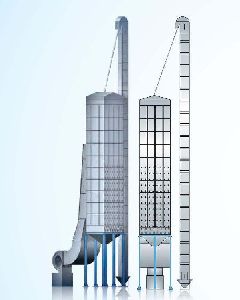

Contact SupplierThe bajaj-cec vertical flow driertm dries better by doing the right thing at the right time. every ginner knows that cotton can’t be cleaned until it is dried and it cant be dried until it is loosened and fluffed so that hot air can penetrate to every fiber. this drier maximizes these processes.

Seed cotton enters the bajaj-cec vertical flow driertm matted, moist and trashy. as the seed cotton enters, it falls onto the first directional cylinder arranged to break up wads and create a loosened stream of seed cotton. the loosened seed cotton slides down baffles made of long thin fingers, with air spacing between each finger, to another cylinder which throws the cotton in another direction. this alternating action is repeated five more times. it is this action that further creates and maintains a stream of seed cotton, increasing the exposure of the heated air to every fiber, maximizing both effectiveness and efficiency.

There are no shelves, screens or grids to roll and twist the cotton before it is dried. the opening and fluffing by the directional cylinders causes the locks of cotton to literally spring open to increase the drying action of the drier.

Features :

| MODEL | 120″ | 96″ | 72” | 60” | 48” |

|---|---|---|---|---|---|

| Length | 120” (3048mm) | 96″ (2438.40mm) | 72” (1828mm) | 60” (1524mm) | 48” (1220mm) |

| Width | 50” (1270 mm) | 50” (1270 mm) | 50” (1270 mm) | 50” (1270 mm) | 50” (1270 mm) |

| Capacity raw cotton per Hrs | 14 Ton per Hrs | 12 Ton per Hrs | 10 Ton per Hrs | 6 Ton per Hrs | 4 Ton per Hrs |

| Hot Air Generator- | - | 500000 kg/cal | 200000 kg/cal | 200000 kg/cal | |