Company Information

Ask for more detail from the seller

Contact SupplierWorking principle

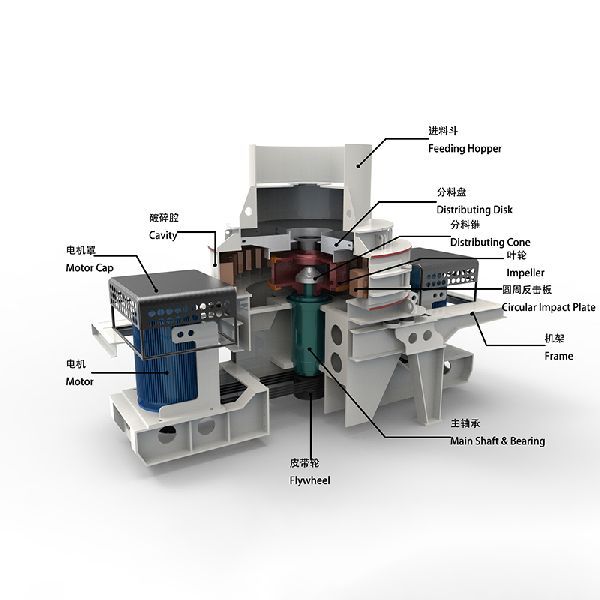

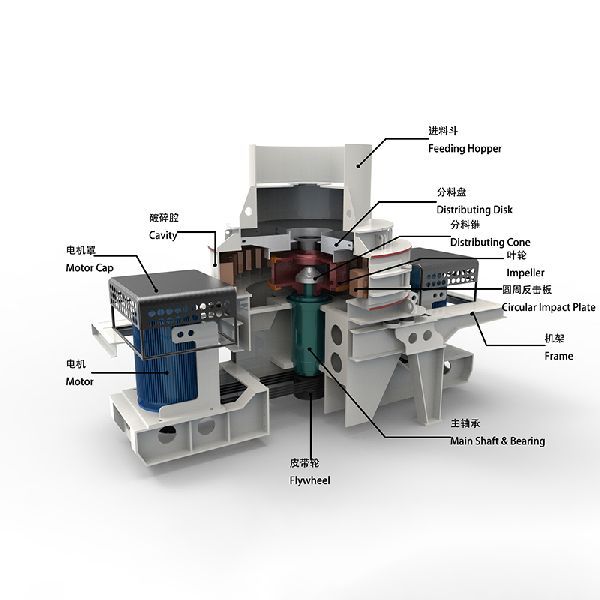

The motor drives the main shaft of the bearing barrel drive part to rotate at high speed. At the same time, the rotor rotates at high speed along with the main shaft. The materials entering the impeller are accelerated by the impeller and then sprayed into the crushing chamber. They collide with the lining materials formed in the crushing chamber and grind with each other. After accelerating the materials, the kinetic energy is obtained and converted into the energy required for crushing or shaping materials. The materials circulating in the crushing chamber for many times are in the circumference. Under the action of surrounding gas eddy current, it is broken and shaped for many times, so as to realize continuous crushing and shaping of materials, and discharge from the lower part of the machine body to form the required finished materials. This crushing method is “stone striking”, which is mainly applied to shaping and crushing of stones. In addition, this equipment is equipped with “stone striking” crushing method, which is different from stone striking: after the materials are ejected from the rotor, they are The impact block installed in the crushing chamber is impacted to accelerate the energy obtained by the material into the energy required for collision and crushing with the impact block. After the impact, the material is directly discharged from the lower part of the body, which can not achieve multiple cycles of crushing in the crushing chamber. This crushing method is mainly applicable to the working occasions with crushing as the main purpose (to provide a large crushing ratio).