Listing ID #36732

Company Information

Ask for more detail from the seller

Contact SupplierSalient Features

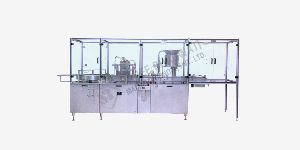

Total cGMP Model.“ No Vial No Filling System”M.S. Frame Structure duly cladded with S.S. SheetContact Parts of S.S. 316LIndividual Servo Motor for Each SyringePLC System with Touch Screen HMIFilling Volume controlled through PLC 3 Level Password setup in PLCMachine can handle vial range from 2 ml. to 100 ml. & Rubber stopper of 13 mm, 20 mm & 32 mm size (With the help of change parts)Rotary Disc Type Pick & Place Rubber Stoppering System suitable for Full Stoppering as well as Half Stoppering (For Lypholized & Non Lypholized Vials “Minimum Vial at infeed & maximum vial accumulation at outfeed, machine stop and auto restart (Optional).Auto Sampling System (Optional)Auto Rejection system for those vials which are not stoppered after stoppering station (optional)Two Track system at the outfeed End one for OK Track and the other one for Sampling / Rejection (Only applicable if the machine is equipped with Auto sampling & Auto Rejection system)Convenient to load Rubber Stopper into the bowl as the Bowl & Vibrator system are mounted on a Frame structure at a nominal height which makes the operator to view and load the rubber stopper as and when required.“No rubber stopper in chute” machine stop system.“ No Vial no rubber stopper” System.Pre & Post gasing system.“ No Vial no gasing system”Nitrogen pressure can be adjusted from HMI“ Low Nitrogen pressure” machine stop systemTriclover Fitting in Syringes which makes the removal of syringe very easyAcrylic Cabinet with Aluminium Structure.All Assemblies under top plate are positioned as for easy cleaning or maintenance.Double dosing for 100ML is also possible.All driving is through High quality imported Gear motor for better machine performance without vibration or leakage of oil of area floor from gear box.Machine speed can be adjusted through A.C. Frequency drive, which is time saving and the machine speed can be easily synchronized with unscrambler and conveyor.Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor.Special clutch devices are provided on Star wheel for safety purpose.Vibrator bowl for rubber stoppering unit support to run machine with total claimed speed of machine.

| Model No. | NKLFRS-200R |

|---|---|

| Direction | Left to Right |

| Production Rate | Upto 180 - 200 Vials/Min. (For 5 ml. Fill size) |

| Fill Capacity | 0.5 ml. to 100 ml ( Upto 50 ml. Single Dose & for 100 ml. Double Dose) |

| Accuracy | ± 1 % |

| Electrical Supply | 10 H.P. |

| Power requirement | 415 Volts, 3 Phase (4 wire system) 50 Hz. |

| Height of Conveyor | Adjustable from 900 mm to 950 mm |

| Dimensions | 3500 mm (L) x 1538 mm (W) x 1638 mm (H) |

| Net Weight | 1200 Kgs. (Approx.) |

| Gross Weight | 1450 Kgs. (Approx.) |

| Type of Rubber Stoppering | Rotary Type |

| Syringes available for different fill volume | 0.5 ml. to 2 ml 2 ml. to 10 ml 10 ml. to 50 ml. |

| No. of Syringes | 08 Nos. |