Company Information

Ask for more detail from the seller

Contact SupplierThe primary applications for Water Bath Heaters include:

• Heating Natural gas prior to pressure reduction manifolds to prevent freezing of expansion valve

• Hydrate prevention

• Heating of process fluid upstream of separation units to enhance separation efficiency

• Heating of crude oil to maintain temperature above the paraffin pour point

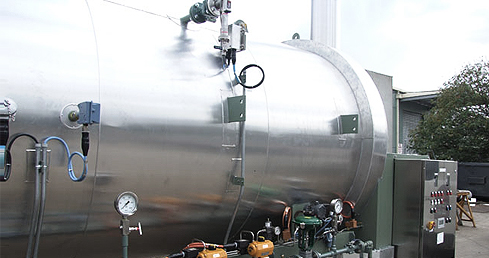

The heater consists of three main components: the shell, the firetube, and the process coil. These components are

carefully designed for each standard size as well as for our customized packages.Fuel (Fuel Gas or Fuel Oil) is burned within the horizontal “U”-shaped firebox immersed in the lower portion of the water bath.

Heat released by the burning fuel is quickly transmitted through the firetube wall to the water bath, maintaining it at the desired

temperature.

The fluid to be heated (wellstream, natural gas, oil, water, etc.) flwos through the process coil of the heater which is immersed in the upper portion of the water bath. Heat is transmitted from the hot water bath through the tube-wall to the fluid inside the process coil.

The heater temperature controller maintains the water bath temperature at the desired level by controlling the firebox fuel gas supply. A temperature of 87 ˚C is considered the maximum temperature for operation. It is preferred to operate the heaters less than 87 ˚C when inlet condition andor outlet temperature requirements allow.

Operating the bath temperature at the minimum temperature required to give hydrate protection in either the pipeline or separator not only saves fuel, but provides maximum liquid recovery in the downstream equipment.