Company Information

Ask for more detail from the seller

Contact SupplierScaling:

Scaling occurs when a mineral film coats the entire heat transfer surface of Heat exchanger OR Condenser. These mineral deposits such as Calcium, lime, Mud and rust rob heat transfer efficiency. This increases energy cost by over 30 %.

Heat Exchangers, Condensers and even Cooling Towers therefore require DESCALING maintenance to improve their efficiency.

Evaporative Condenser:

When water scale is deposited on the heat transfer surface of an evaporative Condenser, the cooling water from the spray head can not efficiently condense the refrigerant gas in the coils. As a result inadequate cooling , over worked machinery and expensive operation is incurred.

Shell & Tube Condensers: Water scale deposits in the condenser coils cause the compressor to kick out on high head pressure and lowers the cooling capacity of the unit.

Cooling Towers:

Absorption Units:

Scaling of Plastic Molding Machines :

How to Get Rid of Scaling :

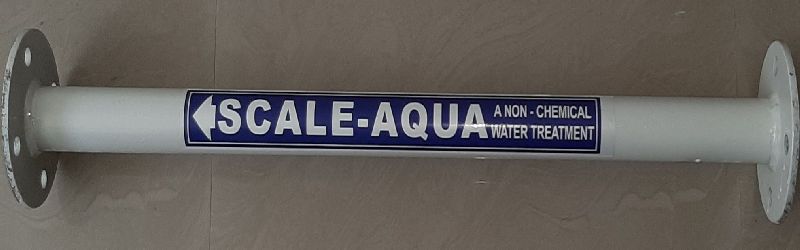

Advantages of Scale Aqua Installation :

| Model | AB | AB | AB | AB | AB | AB | AB | AB | AB | AB | AB | AB | AB | AB |

| Model | C 1 | C 2 | C3 | C4 | C5 | C6 | C7 | C | C9 | C10 | C11 | C12 | C13 | C14 |

| PipDia | 1 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Flo 1 | 3 | 12 | 19 | 25 | 40 | 85 | 133 | 198 | 260 | 565 | 820 | 1135 | 1490 | 1880 |

| Flo 2 | 4.8 | 21 | 27.5 | 44 | 93 | 143 | 210 | 375 | 590 | 850 | 1170 | 1530 | 1940 | 2400 |

| Pipe Dia: Inches, Flo 1: minimum flow M³/HR Flo 2: Maximum Flow: M³/HR | ||||||||||||||