Company Information

Ask for more detail from the seller

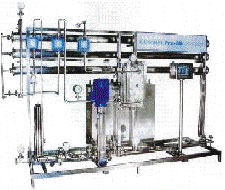

Contact SupplierSOFTENER :

Softener is used for removing Hardness salts (e.g.Ca,Mg. salts of Corbonate,Sulphate & Hydroxides) from water. It consists of lon-Exchange Resin in sodium form.When hard water passes through Softener bed, Sodium ions of Resin are exchanged with Ca and Mg ions and generate Soft water.Once the resin beds are saturated with Ca & Mg, the unit required regeneration with brine salt.

DE-ALKALISER :

It is used for reducing alkalinity of the water.Weak Acid Cation Exchange Resin can remove all Cations which are associated with alkalinity. The alkalinity gets converted to Carbonic acid which splits in the CO2 and water.The CO2 is removed by the de-gassifier.

This is following when the Alkalinity of water is higher than Hardness.

WAC + De-gasser system is usaed when the entire hardness is bicarbonate Hardness i.e. Temporary Hardness. But when Alkalinity is Lower then Hardness,then the Hardness excess of Alkalinity shall be non-Carbonate Hardness i.e. Permanent Hardness.This Hardness can not be removed by WAC resin,in that case split strem and de-gasser system is recommended.Once stream is passed through Softener where as the second stream is passed through SAC.Both streams are mixed and passed through the de-gasser.