Company Information

Ask for more detail from the seller

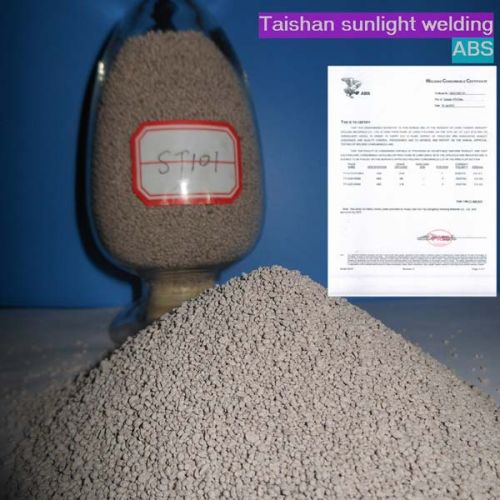

Contact SupplierWe are offering welding flux . Soldering flux ty.sj101

specifications: aws a5.17 f7a2-em12k f7a4-eh14

certification: abs ccs

applications: single and multi-layer welding of

1.api pipes(x52,x60,x70,x80 grade steels)

2.thick-wallstructures of different kinds of high-tensile strength steel

characteristics:

1.ty.sj101g is an agglomerated fluoride-basic type flux

2. Metallurgical behavior: the behavior of silicon and manganese is neutral,

so it is better to weld with wires containing relatively high manganese and silicon.

3. Basicity: 3.1(biiw)

4. As a result of low hydrogen levels(max.5ml100g),low oxygen,sulfur,phosphor levels in the all weld deposites,unform mechanical properties with low temperature toughness are obtained.

5.slag is extremely easy to remove and bead appearance is beautiful in multi-layer narrow gap welding of thick plates.

Ty.sj101 for gas pipes welding.

Welding speed: 120mh

agglomerated flux production line(total:three):

wire yield

point

s(mpa) tensile

strength

b(mpa) elongation

δ5(%) charpy v notch impact strength akv(j)

-20c -40c -50c

em12k ≥400 490-600 ≥22 ≥60

eh14 ≥420 510-600 ≥22 ≥70 ≥57 ≥27

eg ≥460 530-690 ≥22 ≥90 ≥80 ≥42

ea2 ≥500 600-700 ≥20 ≥60 ≥55 ≥34

cautions:

damp flux should be re-dried at 300-350 centigrade for 2 hours.

Rust,grease and moisture on the weldment should be removed before welding.