Company Information

Ask for more detail from the seller

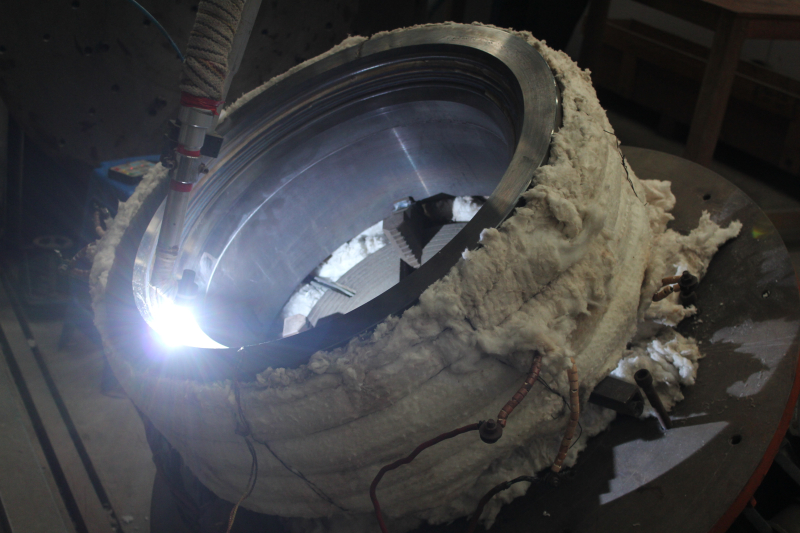

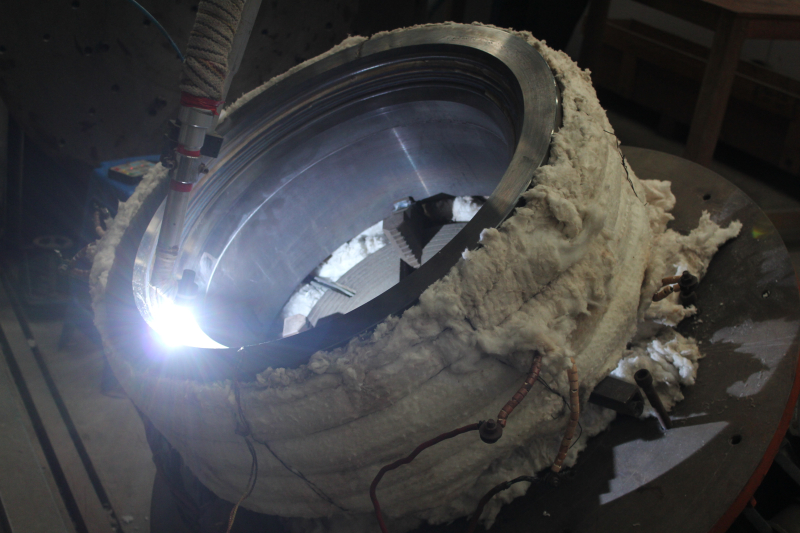

Contact SupplierProcess Overview – Welding is a process of joining metals or thermoplastics by using a high amount of heat generated by a power source. This melts the material to fuse together and form a metallurgical bond which is protected by a shielding inert gas to prevent contamination and oxidation. Few commonly known welding services offered by us include GMAW (Gas Metal Arc Welding), GTAW (Gas Tungsten Arc Welding), SMAW (Shielded Metal Arc Welding), FCAW (Flux Cored Arc Welding) and Laser Welding. While this technology has long been used for joining metals, we also utilize it for overlaying specific alloys on carbon steel and stainless-steel substrate to impart enhanced properties. Our main expertise in this area include :

GTAW – It utilizes a non-consumable tungsten electrode to produce the weld when a filler wire is introduced in the arc protected by a shielding gas. It produces a homogeneous and low dilution metallurgical bond with the base metal substrate and mainly used for deposition of Stainless Steel and its alloys, Nickel, and its variants, Stellite and its variants. Weld overlay followed by PWHT (Post Weld Heat Treatment) makes the welding denser and removes any residual stresses induced by the welding.

PTA – Plasma Transferred Arc is a process used to fuse a metallic coating to a substrate to improve its resistance against wear and/or corrosion. Metal powder is fed into a molten weld puddle (fusion bath) generated by the plasma arc at high temperature (up to 20,000 °C). Deposit thickness can range from 0.6 to 6.0 mm, width from 3 to 10 mm when using a single pass; multi pass welding reaches deposit thickness up 20 mm and width over 30 mm. The deposit microstructure is dense with formation of dendrites during solidification. One of the most important features of the PTA process is the control of dilution which is as low as 5%. It is usually preferred for overlaying of exotic materials such as Nickel and its variants and Stellite and its variants.

Spray and Fuse - It is an extension of coatings done by Powder Flame Spray process wherein the sprayed coating is fused with the base material by application of external heat energy using Oxy-Acetylene torch, Induction coil, Furnace, Laser beam or an external heating source. The coating is taken to solidus temperature (1020 to 1100°C) at which the coating fuses and voids and porosity in the coating collapses making the coating denser and more homogeneous. This also forms a fine metallurgical bond with the prepared substrate which makes the coating capable of enduring impacts. A variety of materials can be deposited by this process to achieve properties required for different critical applications such as Cobalt and its variants, Nickel and its variants, Carbide and its variants etc.

Laser Cladding - It is the use of electrically produced laser light to heat wire or powder material and apply it to a substrate surface. Since the heat input generated by laser is less it produces minimal HAZ (Heat Affected Zone) which is detrimental to the weld quality. Laser cladding is often performed by robotic manipulators and produces a very dense and homogeneous deposit with the least amount of dilution.

Vacuum Brazing – It is a process of joining two similar or dissimilar metals by heating a braze alloy between the components inside a vacuum furnace. The braze alloy has a lower melting temperature than the parent component and melts easily to fill the clearance and form a joint. Vacuum Brazing is preferred where leak tight joints are required mainly in critical Aerospace and Defence components, Automotive and HVAC industries. We specialize in vacuum brazing of nickel and aluminium based filler metals which are available in the form of paste, wire, and foil.

Capabilities

Latest weld overlay and laser cladding technology

Weld overlay facility integrated with heavy engineering tool room

Welding and Cladding processes available – GTAW, PTAW, SMAW, FCAW and Laser.

Welding and Laser cladding of exotic materials such as Nickel and its variants, Cobalt and its variants, Carbide and its variants etc.

Completely automated welding setup capable of welding parts up to 2000mm Dia and 2000mm long

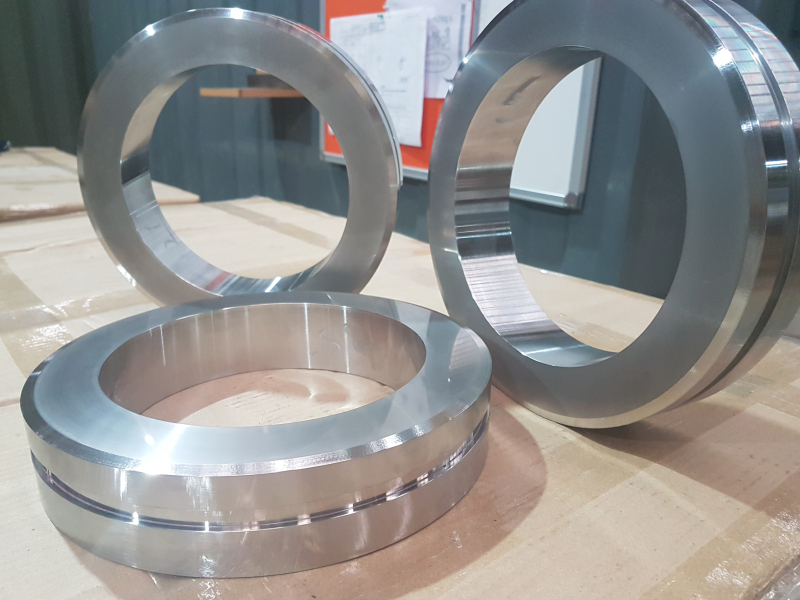

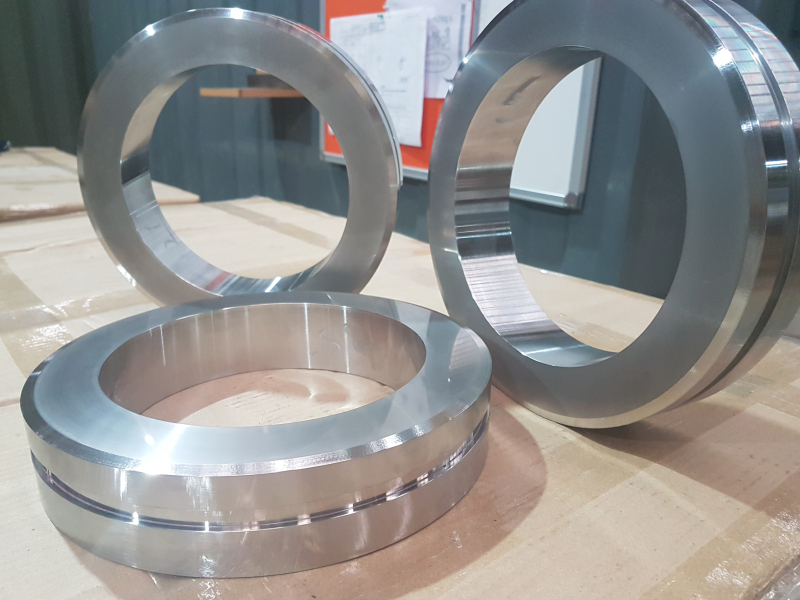

Pre and post machining of weld overlayed parts up to 1500mm Dia and 6000mm long

Grinding of weld overlayed parts up to 800mm Dia and 6000mm long

Heat treatment furnaces for pre and post coated/welded parts up to 2000mm Dia and 8000mm long

Complete end to end manufacturing of weld overlayed/cladded parts and assemblies

Dedicated welding setup for batch and production parts

Qualified welding operators capable of manual as well as semi-automatic welding

Availability of WPS, PQR and WPQ for range of materials qualified by internationally recognized certifying bodies

NADCAP certified High Vacuum Brazing furnaces for Aerospace and Automotive parts

In-house laboratory for microstructure analysis of welded samples including micro-hardness and bond strength evaluation

Welding facility certified to AS 9100 Rev.D and ISO 9001 Quality Management System

Welding shop approved by BHEL and MNC’s such as Siemens and L&T

Application and Benefits

Like plating and coatings, weld overlay finds applications in critical working environments such as Oil & Gas, Steel, Pumps and Valves, Hydraulic, Plastic Extrusion etc.

Few commonly welded overlaid parts include valve spindles, diffusers, shafts, pump casings and rings, mandrels and housings, piston rods etc.

Weld overlay and Laser cladding offer numerous advantages such as :

Wide range of exotic materials can be used in different forms

Flexibility to apply on any base material substrate

Forms a metallurgical bond which gives high impact strength

Enhances wear, abrasion, corrosion, and high temperature oxidation resistance

Improves operational life of part

Reduces downtime and breakdown costs