Company Information

Ask for more detail from the seller

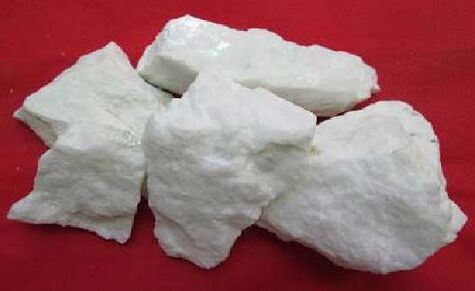

Contact SupplierSodium Feldspar is generally a clean white mineral that sources sodium, alumina and silica along with some potassium and calcium. Nepheline Syenite is often used in similar circumstances; however it has a higher alumina content (often the lower alumina content of soda feldspar provides more room in glaze recipes for alumina sourcing ball clay or kaolin to help suspend the slurry).

In ceramic bodies, potash feldspar is preferred although soda feldspar works as a good flux and can be satisfactorily used in developing ceramic bodies. Potash feldspar has p.c.e. value 10, while soda feldspar has 8-9. Anorthite (the calcium feldspar), though it contains twice as much alumina as soda and potash feldspars and also contains lime which is an important ingredient of glass, is not preferred in the glass industry because it is more refractory (p.c.e. 12). Glass industry prefers to use mainly orthoclase (potash feldspar) because it tends the melt to clear glass while albeit (soda feldspar) tends the melt to a translucent glass.

Sodium used in for glaze preparations

Soda Feldspar is generally a clean white mineral which sources sodium, alumina and silica along with some potassium and calcium. Albeit mineral from which soda feldspar is derived is often tends to be white in appearance compared with the pinkish hue of orthoclase mineral from which potash feldspar is ground. It begins melting around 800C.

In many cases soda and potash feldspar are interchangeable in glaze recipes. However, some differences will be apparent. For example, slightly different color responses will be encountered (i.e. cobalt tends toward purple copper toward blue with soda spar). Sometimes colors will be brighter with soda feldspar. In addition, soda spar has a higher coefficient of expansion and melts earlier and has a shorter range before it begins to volatilize.

Soda feldspar is a clean white mineral with a melting range of 1100-1500C. Soda and Potash feldspar are interchangeable in glaze recipes but there are some differences between them. Soda feldspar melts better than the potash feldspar. Soda feldspar has a higher coefficient than the potash. Soda feldspar is a volatile substance and has excellent moisture absorbent capacity due to which this compound melts when it comes in contact with the atmosphere.

Above are based on our research as well as research of others. However, this document is not contractual and nothing in it constitutes a warranty (expressed or implied) that the goods described are accurate and fit for a particular purpose of the customer. Purchasers are advised to make their own test to determine the suitability.

Potash feldspar is used in various industries.

Silent Features

Applications

| - | SODIUM-01 | SODIUM-02 | - |

|---|---|---|---|

| Silica | SiO2 | 68% (+/- 1%) | 70 To 73% (+/- 2%) |

| Alumina | Al2O3 | 18% (+/- 0.5%) | 18% (+/- 2%) |

| Sodium Oxide | Na2O | 10.00% (+/- 1%) | 8% (+/- 1%) |

| Pottasium Oxide | K2O | 0.5% (+/- 0.5%) | 4% (+/- 1%) |

| Titanium Oxide | TiO2 | Nil | Nil |

| Calcium Oxide | CaO | Nil | 0.25% (+/- 0.05%) |

| Magnesium Oxide | MgO | Nil | 0.25% (+/- 0.05%) |

| Ferric Oxide | Fe2O3 | 0.06% (+/- 0.05%) | 0.001 |

| Loss on Ignition | LOI | 0.001 | 0.002 |