Company Information

Ask for more detail from the seller

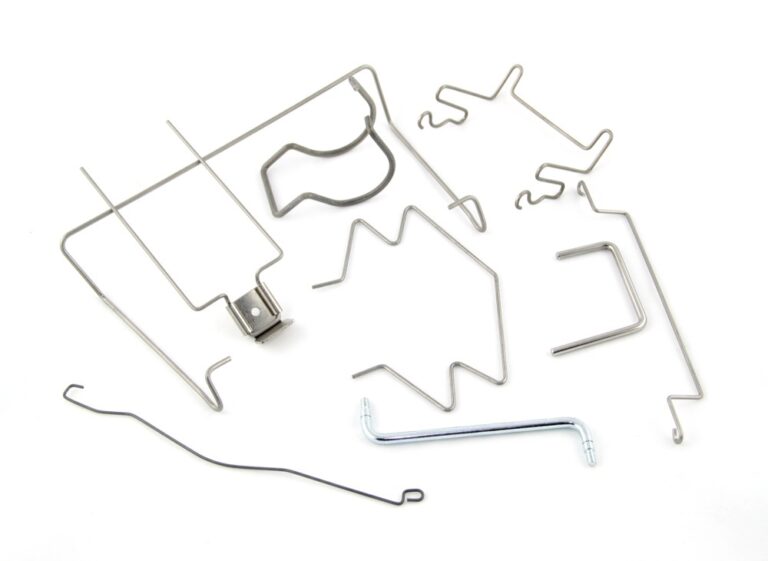

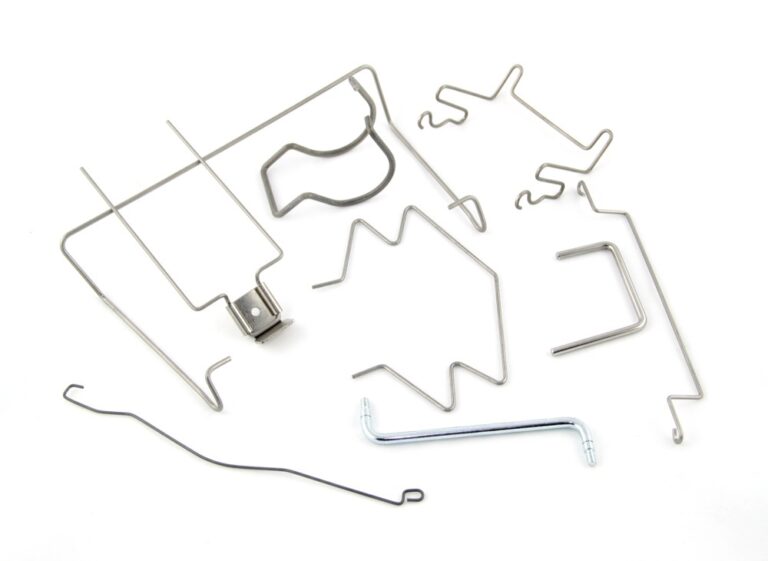

Contact SupplierWire bending is a specialized manufacturing process that involves the manipulation of wire or metal rods into various shapes and configurations, often with precise angles and curves. This technique is widely used across multiple industries, from automotive to electronics, construction, and crafts. Here is a detailed description of the wire bending process: 1. Diverse Applications: Wire bending is employed in numerous applications, including the creation of wire forms, springs, custom hooks, fasteners, decorative elements, and intricate components for machinery and appliances. Its versatility allows it to adapt to a wide range of industries. 2. Materials: Wire bending can be applied to various materials, including steel, stainless steel, aluminum, copper, and even plastic or composite materials. The choice of material depends on the specific application's requirements, such as strength, corrosion resistance, or electrical conductivity. 3. Precision and Customization: One of the key advantages of wire bending is its ability to achieve precise and customized shapes. Advanced bending machinery and computer numerical control (CNC) technology enable the production of intricate and highly accurate wire components to meet exact specifications. 4. Bending Techniques: Wire bending can be accomplished using a variety of techniques, including manual bending, semi-automated machinery, and fully automated CNC bending machines. CNC technology allows for the efficient production of complex wire shapes with consistent precision. 5. Wire Diameter and Thickness: Wire bending can accommodate a wide range of wire diameters and thicknesses, from fine, delicate wires used in jewelry to thick, robust wires employed in industrial applications. The bending process is adjusted to suit the specific wire characteristics. 6. Tools and Dies: Specialized tools and dies are used to shape the wire accurately. These tools are designed to create bends, loops, angles, and curves according to the desired design or engineering specifications. 7. Quality Control: Quality control measures are implemented to ensure that each bent wire component meets the required standards. This includes checking for dimensional accuracy, uniformity, and the absence of defects. 8. Efficiency and Speed: Automated wire bending machines can produce large quantities of bent wire components quickly and efficiently, making it suitable for high-volume manufacturing processes. 9. Versatility in Industries: Wire bending is found in a wide range of industries, such as automotive, aerospace, electronics, construction, medical devices, and consumer goods. It is used in everything from wire harnesses in cars to intricate springs in electronics. 10. Customization and Prototyping: - Wire bending is particularly valuable for prototyping and small-batch production, as it allows for rapid customization and adjustments to design changes without the need for expensive tooling. In summary, wire bending is a versatile manufacturing process that transforms wire or metal rod materials into precise and customized shapes to meet the demands of various industries. Its adaptability, precision, and efficiency make it a valuable technique in the creation of wire-based components and products, from simple wire forms to intricate mechanical parts. Description of Wire Bending Wire bending is a specialized manufacturing process that involves the manipulation of wire or metal rods into various shapes and configurations, often with precise angles and curves. This technique is widely used across multiple industries, from automotive to electronics, construction, and crafts. Here is a detailed description of the wire bending process: 1. Diverse Applications: Wire bending is employed in numerous applications, including the creation of wire forms, springs, custom hooks, fasteners, decorative elements, and intricate components for mach