Company Information

Ask for more detail from the seller

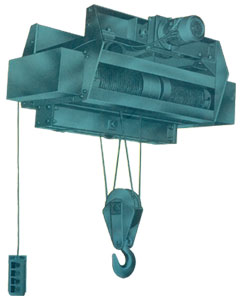

Contact SupplierELEPHANT BRAND" WIRE ROPE HOISTS ARE SUPERB COMBINATION OF MATERIAL AND LATEST TECHNOLOGY...SPECIAL FEATURES:

|

SPECIFIC DESIGN

ADVANTAGES OF 'ELEPHANT BRAND' WIRE ROPE ELECTRIC HOIST: