Listing ID #1765376

Company Information

Ask for more detail from the seller

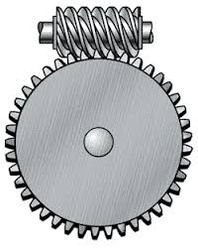

Contact SupplierA Worm Gear is used when a high velocity attrition rate is required between bridged axis shafts which do not cross at a point. Basic Worm Gear can be used but the energy which can be passed on is low. A Worm Gear Manufacturing includes a huge size worm rim with a worm attach meshing with teeth on the outside of the worm rim. The Worm Gear is just like a twined and the worm rim is just like an area of a nut. As the worm is turned the worm wheel is triggered to move due to the twined like activity of the worm. The dimension of the Worm Gear set is usually based on the center range between the worm and the worm wheel.

If the Worm Gear are produced generally as bridge to Helical Gear than the outcome is a high speed point get in touch with Gear. However, generally the Worm Gear is carved using a curved mesh machine in contrast to a straight size. This is known as only one package Worm Gear set. If the Worm Gear is produced with curved structure to successfully cover around the worm wheel the gear set is known as a double cloaking Worm Gear set and has the biggest energy potential for the dimension. Individual cloaking gear sets need precise positioning of the worm-wheel to ensure complete collection teeth get in touch with. Double cloaking gear sets need precise positioning of both the Worm Gear and the worm wheel to obtain highest possible face get in touch with each other.

Worm gears cap sate provide a normal single reduction range of 5:1 to 100-1 and can go easily up to 127:1 or more under rare circumstances. The pitch line velocity is ideally up to 30 m/s. The efficiency of a worm gear ranges from 98% for the lowest ratios to 20% for the highest ratios.

Worm Gear offers a normal single decrease range of 5:1 to 75-1. The message range speed is preferably up to 30 m/s. The performance of a Worm Gear varies from 98% for the maximum percentages to 20% for the minimum percentages. As the frictional heat produced is usually high the worm box must be designed to discharge heat in the environment and oiling of Worm Gears is an important factor. Worm Gear is silent in function. Worm Gear at the higher percentages is naturally self securing - the worm can drive the Gear but not the vice versa. A Worm Gear can offer a 50:1 rate decrease but not a 1:50 rate increase(In practice a worm should not be used to stop a device for safety linked systems e.g. hoists. Some material and managing conditions can outcome in a Worm Gear backsliding).

The Worm Gear activity is a moving activity which results in significant frictional failures. The ideal mixture of Gear materials is for a case solidified allow metal worm (ground finished) with a phosphor brown Gear. Other blends are used for Gear with relatively light amount.

» Used in conveyor systems, in which the locking features, can act as a brake for the conveyor when the motor is not turning.

» One other very interesting usage of worm gears is in the Torsion differential, which is used on some high-performance cars and trucks.

» Mining industry

» Mineral plants

» Sponge iron plants fertilizer plants

» Thermal power station

» Mineral plants

» Chemical plants