Company Information

Ask for more detail from the seller

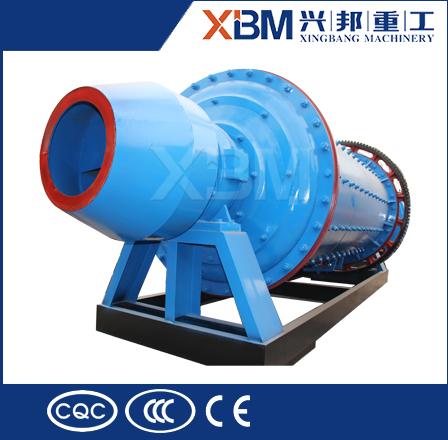

Contact SupplierMachine Description:

Ball mill is a new energy-saving grinding equipment designed by domestic processing machinery experts

after absorbing the newest grinding technology home and abroad. It not only improves the productivity and crushing

ratio, but also expand the application range. It performs an excellent job in secondary crushing, finely crushing and

super finely crushing.

Machine Application:

Ball Mill is an efficient machine for fine powder grinding and key equipment for grinding after the crushing process. There are two ways of ball mill grinding: the dry way and the wet way. It is used to grind many kinds of mineral ores and other materials, or to select mine. Ball Mill is also widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, non ferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other materials.

Machine Structure:

Ball Mill consists of feeding part, discharging part, rotary part, transmission part (reducer, small transmission gears, motor, electric control) and other major parts. The barrel body is wearable scale board.The hollow axis adopts the cast steel; the lining can be replace; the rotating big gear process in the way of casting rolling gear. The barrel body is wearable scale board. The machine runs smoothly and works reliably.

Machine Work principle:

This Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.