Company Information

Ask for more detail from the seller

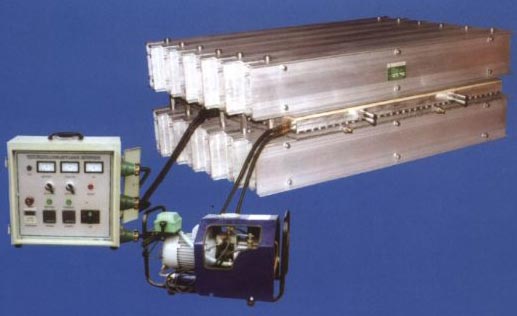

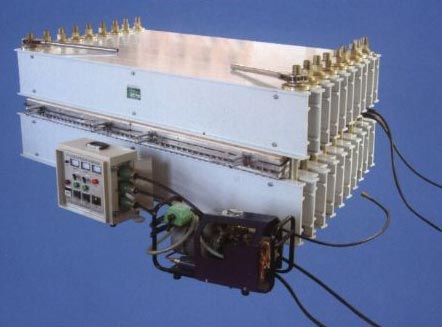

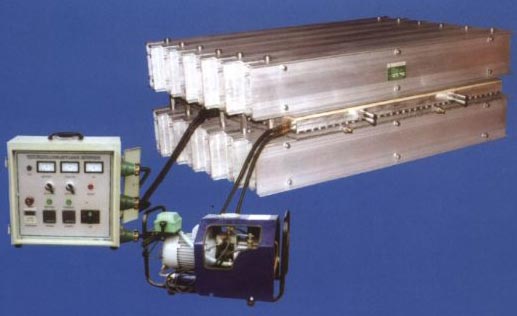

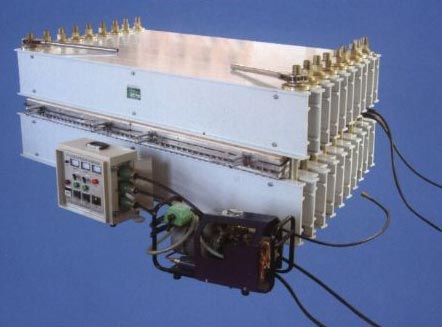

Contact SupplierBased in china, we are one of the trusted Manufacturers, Suppliers and Exporters of XLB Platen Vulcanizing Press Machine worldwide. Extensively functional in making rubber belt, rubber sheet, rubber mold and other rubber production, this machine shows a massive demand. We strictly test these Vulcanizing Press Machines for quality before dispatch. Clients can obtain it from us in different specifications at cost effective prices.

Details :

| Model | XLB-DQ 1500x2000 | XLB-DQ 3000x3000 | XLB-DQ 2000x3000 | XLB-DQ 2600x2800 | |

|---|---|---|---|---|---|

| Total pressure | Ton | 1600 | 3000 | 1600 | 2500 |

| Plate size | mm | 1500x2000x90 | 3000x3000x100 | 2000x3000x70 | 2600x2800x90 |

| Daylight | mm | 200 | 160 | 400 | 200 |

| Layers | 2 | 2 | 1 | 2 | |

| Piston stroke | mm | 400 | 400 | 400 | 400 |

| Close mould speed | mm/s | >=16 | >=16 | >=16 | >=16 |

| Open mould speed | mm/s | >=35 | >=35 | >=35 | >=35 |

| Hydraukic pressure | Mpa | 17 | 16 | 16.8 | 16.5 |

| Cylinder diameter | mm | 550 | 800 | 550 | 700 |

| Cylinder Qty | piece | 4 | 4 | 4 | 4 |

| Mai motor power | kw | 11.0x3+15 | 11.0x2+22 | 11.0x4 | 11.0x3+22 |