Company Information

Ask for more detail from the seller

Contact SupplierAPPLICATION

Monitoring speed is a critical aspect of automation and process safety. The Zero Speed Switch (ZSS), also known as a Speed Actuating Sensing Switch, is a vital device used to detect the stoppage or an unacceptably slow movement of a rotating shaft.

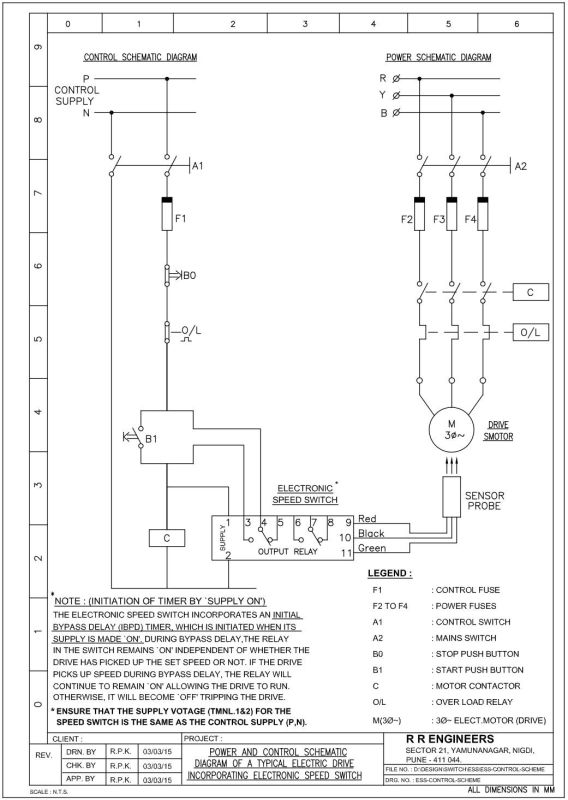

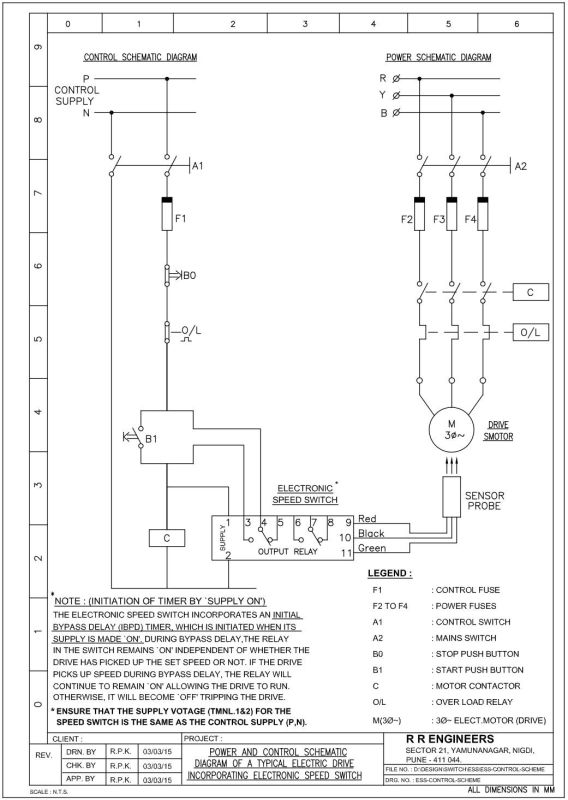

The electronic speed switch is ideally suited for the speed monitoring of critical elements of any material handling system such as conveyors, elevators, crushers etc. The switch sense under speed or over speed conditions in the system by non-contact method and provides output contact for protection, control and interlock purposes. In case of sequential start-up, the speed switch can be used to ensure that the feeder conveyor starts up only when the downstream conveyor has attained desired speed and likewise during shutdown it can be used to ensure that the downstream conveyor stops only when the feeder belt has stopped. Other applications include detection of jamming in the system which results in under speed condition or snapping of the belt which results in zero speed condition at driven end and so on.

CONSTRUCTION

RRE Zero Speed Switch (ZSS) is housed in a dust and weatherproof DMC (Dough Moulding Compound) enclosure, offering IP65 grade protection. It is available in a wide range of speed settings, from 01 RPM to 9999 RPM, supporting both under-speed and over speed monitoring to suit various industrial applications.

For each model, the typical adjustable speed ratio (minimum to maximum speed) is 1:3 or 1:5. This ratio can be customized further based on specific application requirements.

The controller unit includes 03 LED indicators that display:

■ Input power status

■ Pulse input from the sensor probe

■ Relay on/off status

In addition, 04 Digit, 07 Segment LED display provides real-time readings of:

■ Under-speed value

■ Over-speed value

■ Current speed value

■ Error status (in the event of a speed fault)

To avoid false alarms during machine startup, the unit features an Initial Time Delay (ITD) of 30 seconds. It also incorporates Nuisance Tripping Delay (NTD) - adjustable from 0 to 60 seconds-to prevent relay dropout due to brief speed fluctuations.

The ZSS controller supports input power supplies of 110 VAC or 240 VAC (50/60 Hz) or 24 VDC. The standard sensor probe measures 30 x 65 mm, includes a 2-meters cable, and offers a sensing distance of 10 mm. The unit is compatible with both NPN Normally Open (NO) and PNP Normally Open (NO) type of sensor probes. Probes with longer sensing ranges can be provided upon request. The sensor probes are IP 67 grade complaint.

All configuration settings are accessible only by removing the unit's cover, as a standard safety and tamper-prevention measure. 12 pin Terminal Strip is provided for all input and output connections.

ADVANTAGES

■ Non-contact sensing - no moving parts, zero wear and tear

■ Maintenance free - no rollers or couplings

■ Dust/oil/water-proof sensor-suitable for harsh industrial environments

■ Wide speed setting-from 01 RPM to 9999 RPM

■ Support for multiple flag settings (01, 02, 04 & 08)

■ Built-in time delays-for startup bypass and nuisance tripping prevention

■ Under Speed and Over Speed monitoring in a single unit