Listing ID #3960497

Company Information

Ask for more detail from the seller

Contact SupplierThe High Tensile Steel Tube is now widely applied in the global automotive market. In order to achieve higher fuel efficiency and lowering materials costs, thicker tubes and solid bars have been replaced by thin wall High Tensile tubes, which offer lower weight without compromising in strength and safety. With a much higher tensile strength (80~120 Kg/cm²) than conventional steels (40~50 Kg/cm²), this material is highly employed in key areas of cars in for structural (chassis) applications and impact protection.

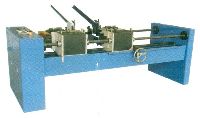

The new SOCO SA-78NCE tube cutting line brings you the latest technology in High Tensile Steel Tube Sawing. Its unique design and cutting system brings the highest saw blade life in such applications, as well as unparalleled performance and speed.