Listing ID #1865694

Company Information

Ask for more detail from the seller

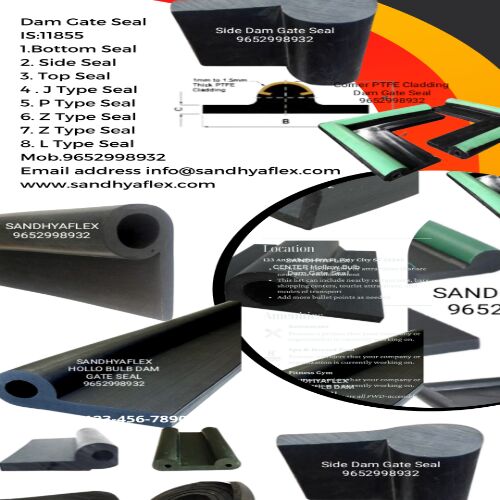

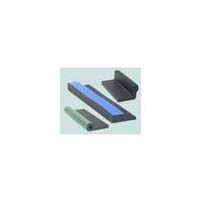

Contact SupplierWre have Experience 10 year in Dam Gate Seal, Manufacturing, Compounding, testing, Installation and Replacement. We are manufacturing wide of range Flat Seal 2mm to 25mm thckl and Rubber Bulb tob, and Side Seal Dia 25mm to 50mm and Width 70mm to 200mm. We Manufacturing With PTFE Cladded, Brass Cladded and MS Cladded Bulb Seal as per IS 11855 Specification. A dam gate seal is a component used to provide a watertight seal between the gate and the dam structure in a water control or hydroelectric power generation system. The gate seal helps prevent water leakage and ensures the efficient operation of the dam. The key features and characteristics of a dam gate seal include: 1. Material: Dam gate seals are typically made of durable and resilient materials that can withstand the hydraulic forces, pressure differentials, and exposure to water. Common materials used include rubber compounds, such as natural rubber or synthetic elastomers like neoprene or EPDM (ethylene propylene diene monomer). 2. Design: The design of the gate seal depends on the specific requirements of the dam structure and the type of gate system used. The seal is typically custom-made or fabricated to fit the specific dimensions and shape of the gate and the sealing surfaces. 3. Watertightness: The primary function of a dam gate seal is to provide a watertight barrier between the gate and the dam structure. The seal is designed to minimize or eliminate water leakage around the gate, ensuring effective water control and preventing loss of water or potential structural damage. 4. Compression and resilience: Dam gate seals are designed to compress and create a tight seal when the gate is closed against the dam structure. The seal must have sufficient resilience to accommodate movement of the gate and changes in water pressure without compromising the seal integrity. 5. Durability and resistance: Dam gate seals are exposed to various environmental conditions, including water, sunlight, and temperature variations. They are designed to be resistant to UV degradation, water absorption, ozone, and other factors that can degrade the material over time. 6. Maintenance: Regular inspection and maintenance of the dam gate seal are necessary to ensure its proper functioning. This includes checking for signs of wear, damage, or deterioration and replacing the seal if necessary to maintain its effectiveness. The selection and design of a dam gate seal depend on factors such as the water pressure, gate size, gate type (e.g., sliding gate, radial gate, or crest gate), and specific project requirements. Engineering consultants or manufacturers specializing in dam gate systems can provide guidance and expertise in selecting the appropriate seal for a particular dam application. The application of a dam gate seal is primarily in dam and reservoir structures to provide a watertight seal between the gate and the dam body. The seal plays a crucial role in ensuring the proper operation, water control, and stability of the dam. Here are some key applications of dam gate seals: 1. Water Leakage Prevention: The primary function of a dam gate seal is to prevent water leakage through the gate when it is closed. It forms a watertight barrier between the gate and the surrounding dam structure, ensuring that water is effectively contained within the reservoir and doesn't seep through the gate and cause uncontrolled flow or erosion. 2. Water Level Control: Dam gate seals are essential for maintaining precise water levels in the reservoir. When the gate is closed and properly sealed, the seal helps to regulate and control the release of water from the reservoir. This allows for efficient water management, flood control, and water supply distribution downstream. 3. Structural Stability: Dam gate seals contribute to the overall structural stability and integrity of the dam. By providing a secure seal between the gate and the dam, they help distribute water pressure evenly, redu