Listing ID #3813846

Company Information

Ask for more detail from the seller

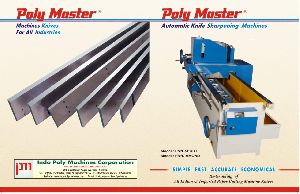

Contact Supplierknife grinder machine are widely used in the all kind of plywood (panel), veneer making and woodworking companies for grinding, re-grinding (sharpening) the log peeling machine’s knives (blades) or veneer lathe machine’s knife. There are 56” (1422mm), 72” (1830mm), 96” (2450mm), 108” (2750mm) grinding machines model and other size models according to our customer’s requirement. Machine’s construction extra heavy duty m.s. Fabricated body & body is completely covered. This machine has vibration less, so during operation performs leading finishing working.

the slide of the machine is made from cast iron for smooth running. Heavy duty pressure valve is made from cast iron to holding the knife (blades) for leading working and fine quality sharpening of the knives. In this machine has a heavy duty cast iron stone rotor for holding the stone pieces to fine grinding. In knife grinder machine has water lifting pump that is used for providing cooling and preventing heat, because during the time of knife grinding operation heat is created between knives and grinding stone. The machine is fitted with leading quality branded electrical panel and electric motors.

we have manufacturing this machine with the using of advanced discovered technology on the scientific way with leading services and technical support forever.

machine’s features:

models are available sec-pkgm 56″(1422mm), sec-pkgm 72″(1830mm), sec-pkgm 96″(2450mm), sec-pkgm 108″(2750mm) and other our customer’s requirement.