Listing ID #2564566

Company Information

Ask for more detail from the seller

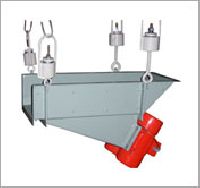

Contact SupplierOur Electromagnetic Vibrating Feeder is capable enough to handle all types of materials such as hot, damp, lump, dusty or abrasive for proportioning and bending, packing, mixing, weighting, sprinkling, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc. Electromagnetic Vibrating Feeder is easy to use and delivers efficient performance.

Advantages

| Type | Feeder Size Width x Length in mm | Capacity TPH for material weighing (100 Lbs/cu.ft) 1600 Kgs/cu.mt | Power Consumption (Approx) in Watts |

|---|---|---|---|

| VIBRO 101 | 315 x 500 | 1 | 175 |

| VIBRO 202 | 400 x 750 | 2 | 300 |

| VIBRO 303 | 630 x 780 | 3 | 475 |

| VIBRO 310S | 800 x 1000 | 10 | 500 |

| VIBRO 420SS | 1000 x 1250 | 20 | 550 |