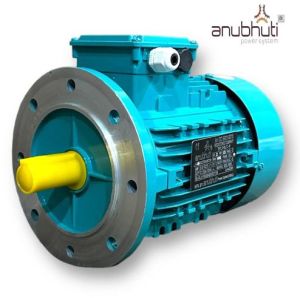

Welcome to Anubhuti Power System

Established in the year 2014, we, “Anubhuti Power System” are involved in manufacturing and supplying a remarkable range of electric motors, industrial gearboxes, coolant pumps, and worm gear reducers. The entire range of products is developed.. Read More

-

Partner

Mr. Rajesh patel

-

Year of Establishment

2014

-

Primary Business

Manufacturer

-

Number of Employees

21 - 50

-

Annual Turnover

Rs. 5 to 25 Crore Approx.